(Author: Judy Lin, Chief Editor, LEDinside)

Color conversion is a challenge for micro-LEDs where pixels can approach sizes smaller than 5 microns, particularly in micro-display applications for mobile devices where overall size, as well as efficiency are all important. Traditional phosphors and even quantum dots (QDs) are not applicable to the micron sized LEDs, principally because of the thickness of material needed.

Advantages of quantum well color conversion technology

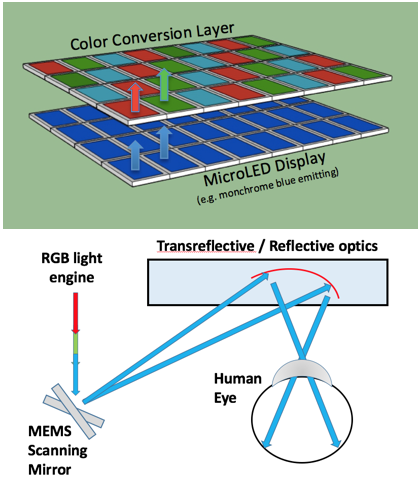

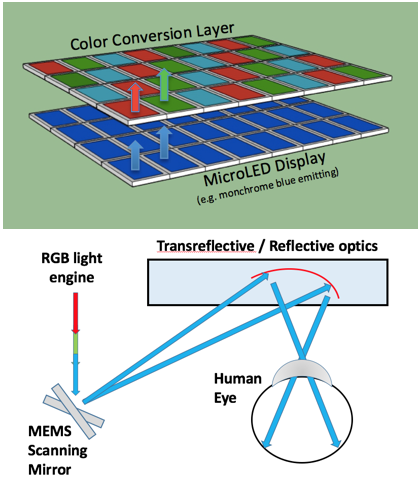

Micro-display manufacturers are attempting various solutions to obtain RGB color in micro-LEDs that are intrinsically monochrome, including rapid assembly of individual RGB LED micro-die, or turning to quantum dots (QD), but New Jersey-based startup VerLASE, a spin-off of Versatilis, is developing a novel solution employing wafer scale, inorganic thin film structures consisting of a novel resonator cavity around semiconductor Quantum Wells (QWs) to convert light to the desired color.

Transfer technologies for assembling die are difficult as pixels scale below 10 microns, as is bonding the CMOS driver circuitry, while the thickness of phosphor or QD material needed to fully absorb LED pump light vis-à-vis smaller pixels makes them impractical for micro-LEDs, explained VerLASE CTO and co-founder Ajay Jain. Neither approach is very efficient, he added, if only because emission is omnidirectional, while significant efficiency gains can be had by directionality and cone angle.

|

|

VerLASE's patented Chromover™ Technology, color converting technology for near-eye micro-LED display applications, such as virtual reality or augmented reality applications. (Image courtesy of VerLASE) |

Advantages of using completely inorganic QWs over QDs include higher efficiency, and higher reliability during the manufacturing process, insensitivity to environmental factors including moisture, oxygen, and longer lifetimes. The inorganic QWs can also be used on-chip or remotely solving the thermal management issues associated with QDs. Moreover, VerLASE’s color converter can be pixelated to very fine pitch to match almost anyone’s micro-LED technology.

QWs are defined as thin film semiconductor structures that derive most of their special properties from the quantum confinement of electrons and holes in thin layers of one semiconductor material that acts as a “Well” sandwiched between other semiconductor “barrier layers[J1] ”. They are like QDs but in a 2D aspect and can be made of similar materials.

In VerLASE’s patented technology, the QWs are typically made of crystalline II-VI semiconductor thin films that can emit green or red colors more effectively, filling the color gap of InGaN materials that are currently only capable of emitting blue and violet light.

The 2D converter structures synthesized from materials similar to QDs can be of zinc selenide, zinc cadmium selenide, or other inorganic chemical compounds that are vacuum deposited using equipment similar to MOCVD in InGaN LED production. Processing thin films in a vacuum chamber ensures better material quality, performance and uniformity from a production perspective, explained Jain.

By comparison, QDs are generally less reliable because they rely on colloidal chemistry in a beaker that is difficult to control, especially when synthesizing uniform particles. Moreover, QDs are typically dispersed in an organic host, resulting in high sensitivity to moisture and oxygen, and requiring suitable barrier designs, which can substantially raise manufacturing costs. According to an industry source, the gas barrier materials used in QDs can cost more than NT $500 (US $15.66) per gram and typically cost around US $30-40 per gram.

Since the QWs are made using conventional, scalable, vacuum processes, VerLASE is capable of slashing manufacturing costs in production. Using an optimized QW structure, the semiconductor thin film can be < 1 micron thick, depending on performance requirements. In contrast, QDs will require 7 – 10 microns layer thickness for equivalent performance due to the host matrix. For micro-LED displays with sub 5 micron pixel size, all these attributes will play a part.

VerLASE’s patented technology includes a novel resonator, consisting of optical thin film coatings on either side of the QW, which enables the QWs to absorb almost all the pump light. This enables very-thin 2D film structures that can be tailored to meet whatever the client’s micro-LED architecture demands.

Responding to why VerLASE chose to work with 2D LED structures rather than nanowire 3D based technologies, Jain responded, “We believe 2D LED the most mature but it is monochrome with no good solution for color as pixel sizes shrink.”

In 2D LEDs with color filter designs, white light is first created from the blue or violet LEDs using color converting materials such as phosphors, QDs or QWs. But the white light is then color filtered to get RGB. “The problem of using color filters is right off you lose 66% of light because for the red pixel you will remove the blue and green photons, for the blue pixel you will remove the red and green photons,” said Jain. “It is a very inefficient approach.”

VerLASE’s technology enables direct conversion of the native LED light into Red, Blue or Green of desired wavelength, minizing light emission lost in traditional white light converter designs. Moreover, by judicious design of the resonator, the directionality of the emission can be controlled. VerLASE’s QW approach with a resonator can directly impact the energy consumption in a device, which is important in micro-LED applications.

VerLASE’s color converting technology is targeting near-eye displays for AR applications, which emphasizes high performance for small pixel displays.

“We believe 2D LED transfer or white light /color filter approaches will not ultimately meet requirements as pixel sizes get smaller, and a better color conversion technology is needed” said Jain, “We believe we can play a significant role in near eye displays in the future.”

The company’s patented Chromover™ color conversion technology, which was granted U.S. patent No. 9,354,366, is especially designed for this market sector, and can down convert color very efficiently from inexpensive blue and violet light sources, such as LEDs or laser diodes into any color in the visible range. It can pixelated to convert multiple colors on a single chip. Moreover, the colors can be optimized for the ideal greens and reds needed for projecting images in Near Eye Displays (NEDs), VR, AR and even large projectors. The technology is designed to integrate with micro-LED displays for next generation NEDs and AR applications.

The Company has been approached by interested manufacturers in AR-display related industries, but declined to reveal details about ongoing partnerships, due to signed non-disclosure agreements (NDAs).

VerLASE operates on a fabless model, and is open to talks with interested partners, investors and manufacturers in Taiwan and elsewhere.

VerLASE’s color conversion technology is not limited to the visible, but can also be adapted in the future to specialty lighting applications, such as UV and IR lights, and to lasers, with so-called optically pumped VCSELs. In the short term, however, VerLASE’s technology will probably make its way as an enabling color converting technology for micro-LED VR and AR displays.

Reference:

[J1]http://www-ee.stanford.edu/~dabm/181.pdf

[Editor's note: The price for quantum dot gas barrier in the original article was referring to NTD currency rather than calculations in USD. This has been changed to: "the gas barrier materials used in QDs can cost more than NT $500 (US $15.66) per gram and typically cost around US $30-40 per gram."]