The second day of IR+UV Expo 2015 special forum that took place in late April in Yokohama, Japan started off with a semiconductor components for laser diodes (LD) and UV LED developments presentation by a senior researcher from Japan’s prestigious research institute, Riken.

In the future manufacturers will be aggressively developing semiconductor components for LD and UV LEDs, said Hideki Hirayama, Chief Scientist, Quantum Optodevice Laboratory, Riken. The industry is highly anticipating LD and UV LED semiconductors with a wavelength between 250 to 350 nm applications. This is mainly because it is stimulated by UV LEDs, and to achieve high white light CRI, the driver circuit design is very simple. To achieve high luminous efficiency, UV LEDs in the 220-350 nm range face two major issues:

1) AlGaN has a relatively low luminous efficacy, internal quantum efficiency (IQE) is usually less than 1%.

2) It is very difficult to make P-polarized AlGaN, electron injection efficiency is usually less than 8%.

In the future by developing low dislocation density AlN and changing the In group composition, IQE can be raised above 50%-80%. Improvements in multiple quantum barrier (MQB) can also raise electron injection efficiency to more than 80%. External quantum efficiency (EQE) can also be improved in the future to 20% by using p-GaN to transfer the epilayer onto a AlGaN buffer layer that is later patterned, which is projected to improve EQE by 20% in the future.

DOWA is a Japanese UV LED chip and package manufacturer. The company not only released its 280 nm UV LED products during the seminar under 20mA it can reach 2mW. Visible effects can be seen in microbiology experiments after 10 seconds of illumination. It is estimated once the company develops 260 nm wavelength products, it can be applicable to UV water purification, sterilization of surgery equipment or other related applications.

|

|

DOWA UV LED product presentation. (LEDinside) |

Currently UV curing LED applications are shifting towards nanoimprint lithography, by using molds to broaden the module to 100 nm, said Kantaro Taki, Associate Professor, Natural System, Institute of Science and Engineering, Kanazawa University. Nano patterned substrates can be created by using UV curing and demolding. The LED market will continue the trend in developing high efficiency LEDs, which is a positive future trend.

PlayNitride offers integrated services including utilizing white laser and UV LED light products. Due to PlayNitride’s adoption of laser light sources, its irradiation range can reach 600 meters, and highest illumination within 25 meters can reach 560 lux, with future application markets probably in marine lighting applications.

|

|

PlayNitride employment of laser products. (LEDinside) |

The company has also launched 700W and 1,900W UV LED light modules that separately use air cooling and water cooling systems. The typical irradiance of the 700W UV LED light module is 2W/cm2 when operating within 70 mm range, while as the 1,900W UV LED light module’s typical irradiance can reach 5W/ cm2. The product applications include UV resins curing and printing.

|

|

PlayNitride Line Type UV LED Irradiant unit. (LEDinside) |

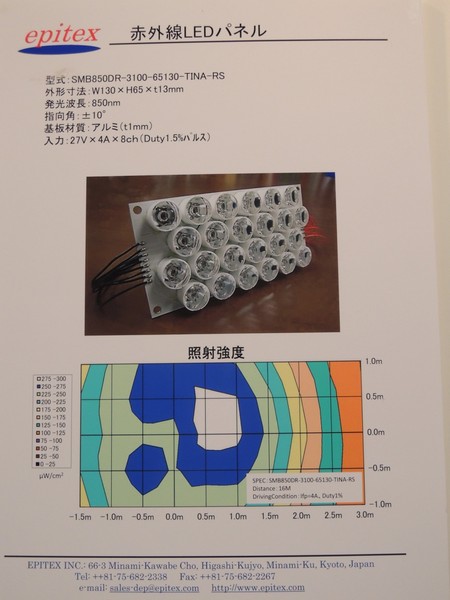

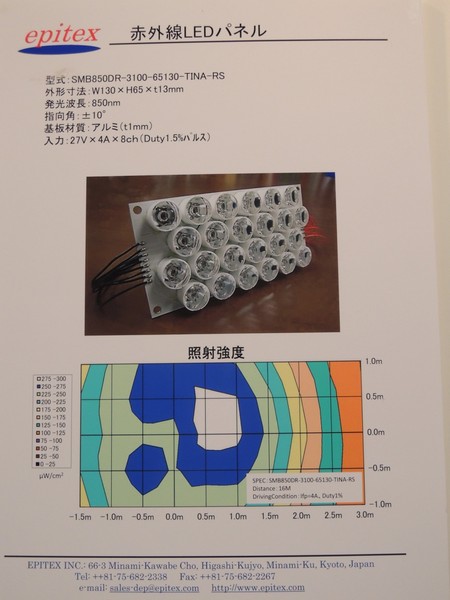

Epitex has 40 years of experience in the industry. The company has been developing and selling UV and IR LED chips (365 nm-1600 nm), LED packages, and modules. The company also released EDC and SMBB products that use aluminum substrates, silicon lenses products. The beam angles can be customized from 10° to 60°. At the same time, 30W UV LEDs use 2A, 20V drivers. The UV air cooling system products have adopted 395 nm wavelengths, the products emphasize light uniformity and are applied in curing equipment market.

|

|

|

Epitex UV and IR LED products. (LEDinside) |

The 850 nm IR products can use tertiary optics design for redesigning its final directional beam angle, giving it more uniform light. Street surveillance systems is a potential application market for these products.

The UV LED market has continued its growth momentum, aside from improving UV LED product efficiency, technology advancements, and system integrations, UV adhesive manufacturers in curing also have an important market role. Major manufacturers including Shin Etsu Chemical, Phoseon, Summers Optical and Parqit. Parqit is mainly focused 565 nm wavelength, and has been developing different wavelength UV Expoxy products and highly reflective materials. The company’s UV curing shrinkage rate is close to 1%, and cost advantages has been Parqit’s major advantage.

|

|

Parqit UV LED curing. (LEDinside) |

(Author: Joanne Wu, Assitant Manager, Research Division, LEDinsidehttp:// Translator: Judy Lin, Chief Editor, LEDinside)

CN

TW

EN

CN

TW

EN