SEMICON Taiwan 2019, as a key event of the semiconductor industry, was held from September 18 to 20 at Taipei Nangang Exhibition Center in Taiwan. More than 700 exhibitors across the world participated in the show with focuses of smart applications, autonomous electric vehicles and more, attracting about 50,000 visitors to explore the latest technology development.

During the show, LEDinside noted that several leading semiconductor equipment providers unveiled solutions and systems of Micro LED and Mini LED. The industry players are cooperating to build an eco-system for improving chip manufacture, optimizing production process as well as enhancing inspection and repairing for the next gen display technology, hoping to push smart display innovation.

US-based equipment provider VEECO introduced its product series for advanced optoelectronics technology including Firebird, a new ALD platform for front-end semiconductor application. The new product is able to process varied size wafers in a larger amount, targeting special applications. By adding ALD passivation layers to Micro LED production process, Micro LED brightness can be boosted.

Furthermore, VEECO’s MOCVD equipment Propel can produce wafers that fulfill the requirement of high wavelength uniformity for Micro LED. VEECO said that a uniformity of 0.7nm across the waver can be achieved by Propel.

ASM Pacific also showcased its strengths in next generation display technology. The company exhibited its solution for fine-pitch display, AD 420, to show the high speed and high accuracy pick-and-place process. Apart from its handling capability for 3*5 mil Mini LED chip, the system also enables a transfer capability of 30,000 UPH.

Kulicke & Soffa (K&S) focused on smart manufacture solution for Industry 4.0, revealing integration systems, KNet PLUS and Auto OLP 2019, to connect equipment for systematized operation monitoring.

The equipment supplier based in Singapore has worked together with Rohinni to develop PIXALUX™ die bonding solution for the rising Mini LED market. The system can process Mini LED (100µm*100µm) with an efficiency of 180,000 units per hour. Its placement accuracy even reaches ±10µm. K&S is still pushing development for better efficiency and accuracy for display applications for its Chinese clients.

National Instrument, who specializes in semiconductor equipment testing, introduced several automotive testing and inspecting system at the show.

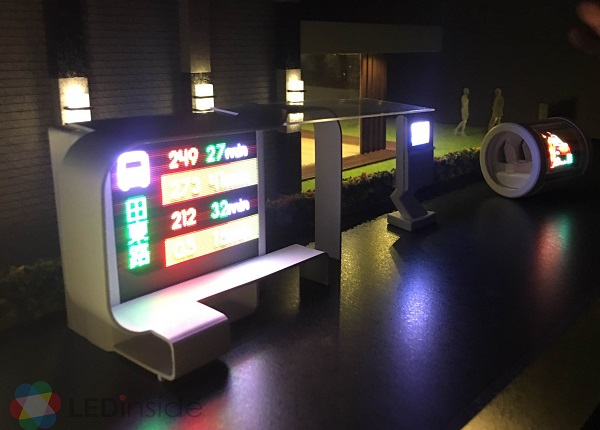

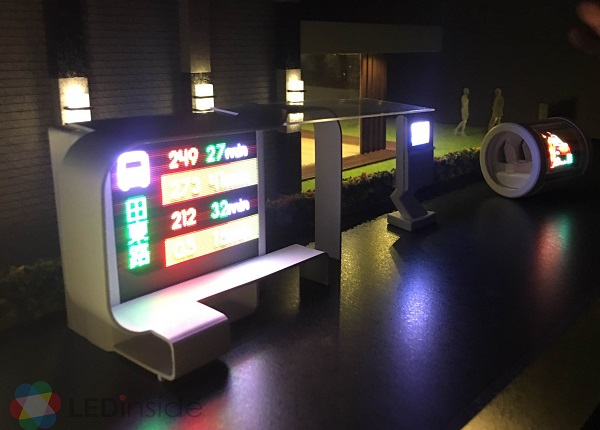

Meanwhile, Micro LED company PlayNitride built a room showing the possibility of Micro LED and Mini LED display applications in the future. Visitors found out how transparent Micro LED display can be used as windows for autonomous vehicle to show information or providing entertaining services on the road. It can also be a big window at home that turns into a large TV when needed. The Micro LED technology developer created a vision of how smart display technology can bring revolutions to our live.

CN

TW

EN

CN

TW

EN