Micro LED technology moved steps forwards since 2019 with worldwide companies showcasing their Micro LED products at big trade shows. LEDinside has noted in “2019 Micro LED Next Generation Display Key Technology Report” that featured with high brightness, high contrast, high response time and power saving, Micro LED technology would suppress other display technology such as LCD and OLED. A wider range of applications including watches, mobile phones, automotive displays, AR/VR devices, monitors, TVs and large displays can also develop towards a higher level with the support of Micro LED.

Since the manufacturing process of Micro LED is still complex and the requirements have become stricter, players in the supply chain, from chip makers, equipment providers to technology developers and panel manufacturers are all working together to enhance the process, aiming to reduce cost and realize product commercialization.

The Swedish-American Micro LED company glō, with years of research in Micro LED, is able to provide RGB full color Micro LED solution as well as mass transfer technology solutions. LEDinside was honored to have a conversation with Fariba Danesh, CEO of glō, to understand how the company’s technology helps to reduce Micro LED production cost and to speed up volume production of Micro LED products.

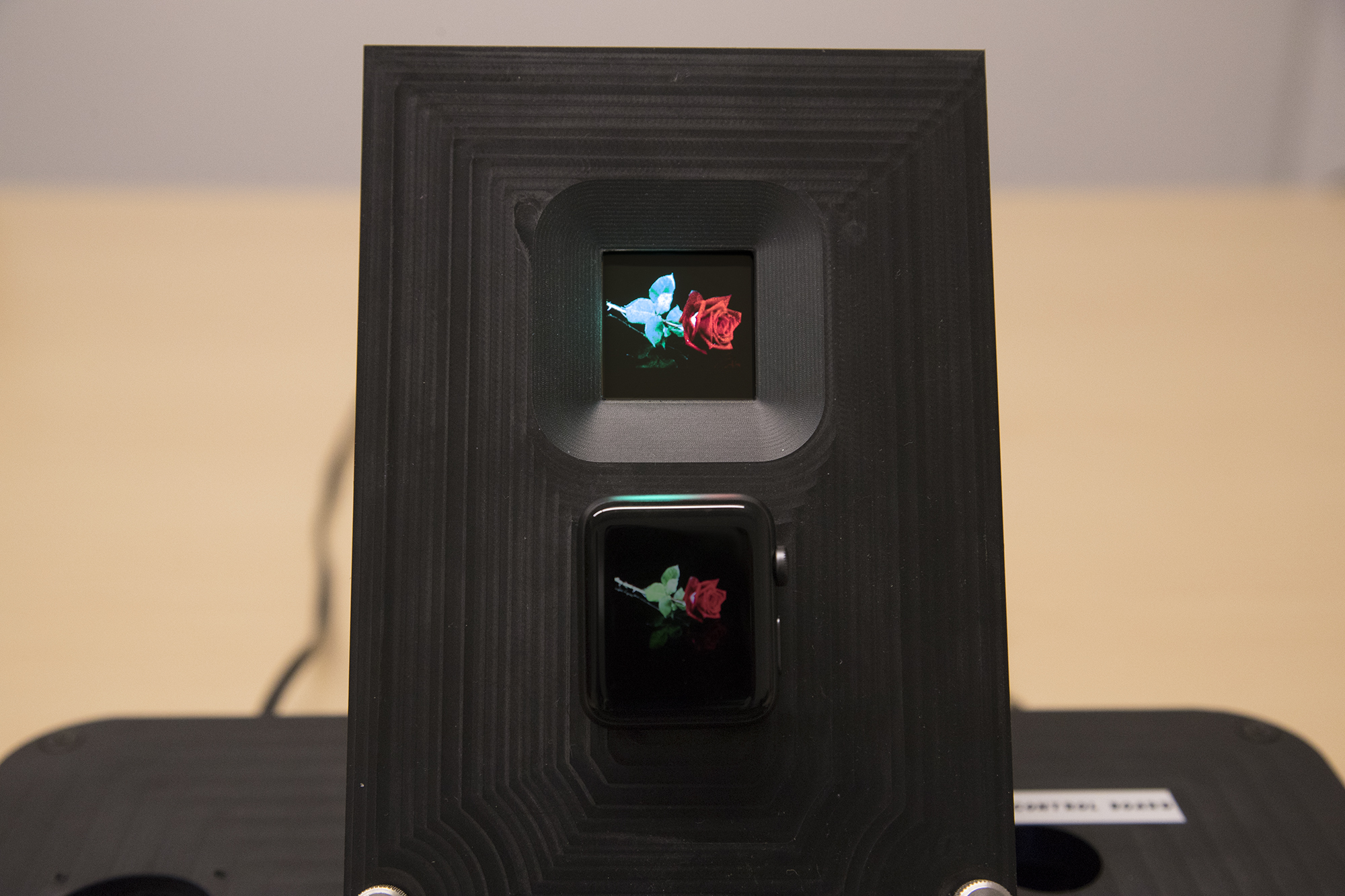

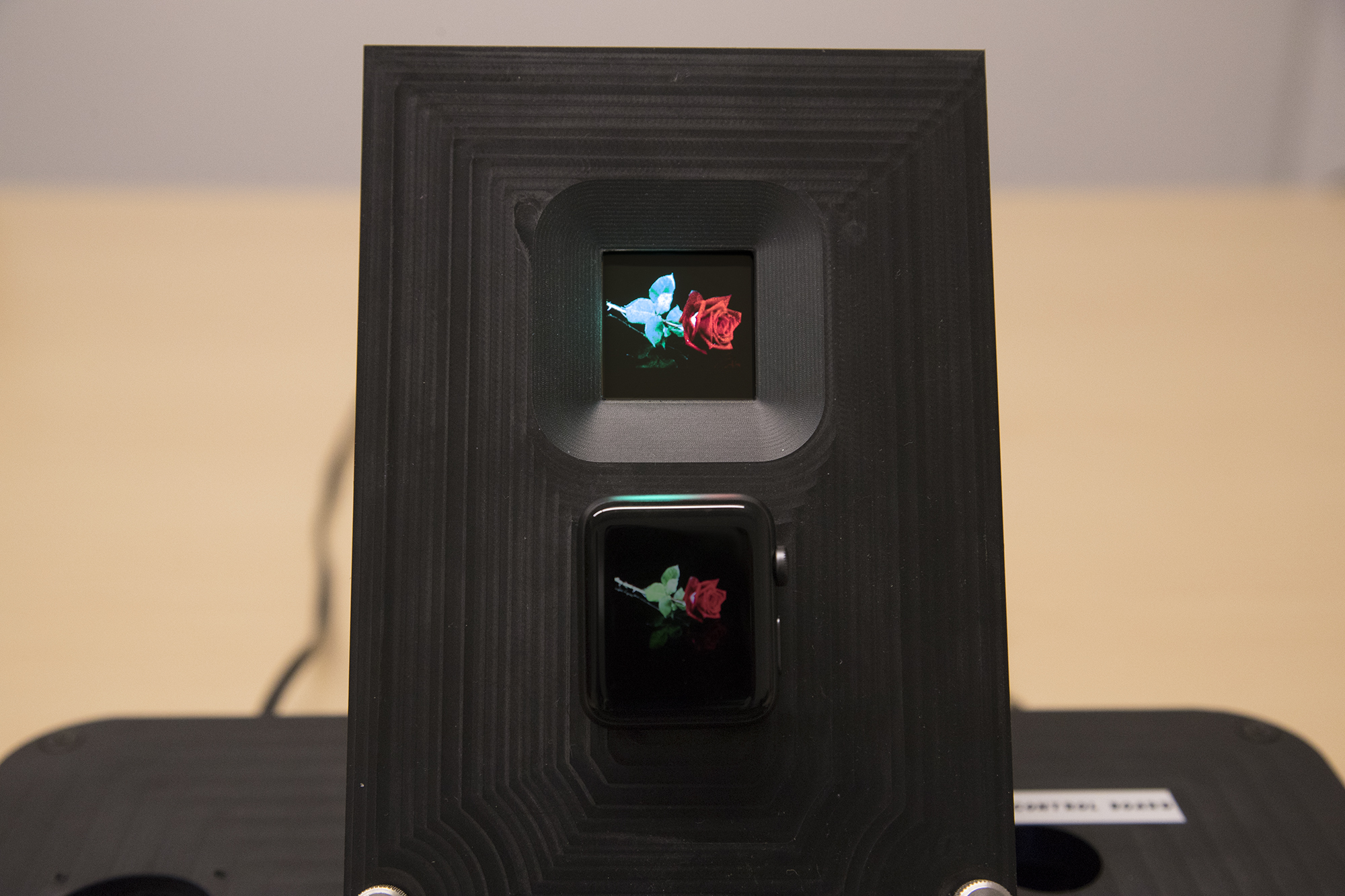

(Image: glō)

glō is a vertical integrated Micro LED company offering LED device design and materials from epitaxy production to subsequence process including mass transfer and bonding. glō’s Micro LEDs are made to fit its own transferring technology.

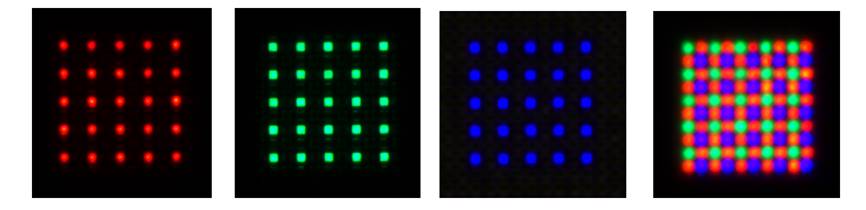

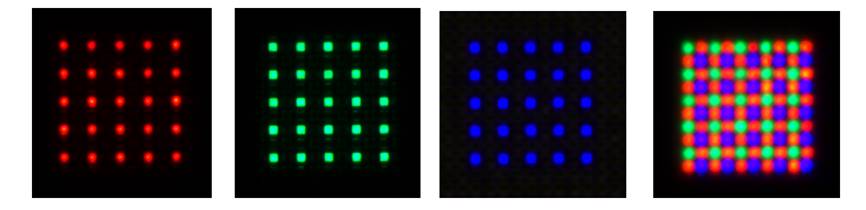

With around US$180 million investment and years in Micro LED research, glō developed the capability of producing InGaN Micro LEDs in RGB colors without color conversion. With existing MOCVD equipment, glō is able to manufacture InGaN on sapphire wafer for Micro LED. InGaN semiconductor is featured with longer life times and better reliability. Moreover, realizing all three color on the same material would scale down production complexity while improve color uniformity. The technology also enables glō to manufacture smaller Micro LED with less cost but still reach performance requirement.

(Image: glō)

The Micro LEDs can then be transferred to targeted backplanes via glō’s proprietary solutions. With the know-hows, glō have been cooperated with different display companies, providing transfer technology on different backplane substrates including glass LTPS and silicon CMOS with diverse pixel layouts for various Micro LED applications.

Danesh noted that glō has licensed its transfer technology to display companies and offers customized solutions accordingly. So far, the company have achieved seven different Micro LED display designs in sized 0.55-inch to 5.5-inch with ppi from 204 to 6000.

glō owns a wide range of patented technologies covering GaN Micro LED, flip chip GaN device design and mass transfer solutions. As a vertical integrated Micro LED solution provider, the unique technology of glō will support acceleration of Micro LED commercialization.

CN

TW

EN

CN

TW

EN