LEDs have become a ubiquitous part of our lives, finding their way into our big screen HDTV’s, into our cars, on our streets, at work and in our homes. The global LED lighting market is booming now as LED prices have dropped significantly over the past few years. However, we are on the verge of a 2nd revolution in LED lighting. The next generation of LED optics will deliver LED lighting that is more comfortable, safer, very high quality and digitally connected, all at affordable prices. Light Polymers, a San Francisco-based nanochemistry startup, is eyeing the LED lighting industry with its unique and disruptive proprietary lyotropic materials technology.

Light Polymers specializes in synthesizing lyotropic materials for a variety of applications. Now, leveraging this unique chemistry for LED down-conversion technology, the company is about to debut the new Crystallin® product lines that include architectural downlights, lights for beauty care, red-light therapy, grow lights for plants fish and animals, professional photography and advanced personal lighting. The downlight product lines will be introduced first, launching in select Asian markets this August through specific selling partners as well as online. The products will debut in the US in November.

|

|

Crystallin Gold Downlights installed in office setting. (Light Polymers/ LEDinside) |

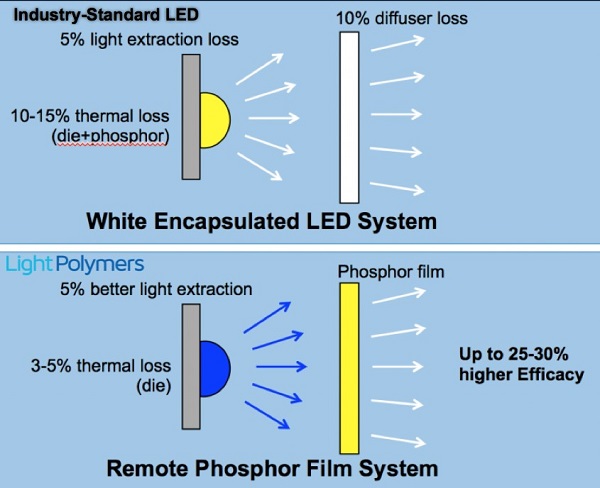

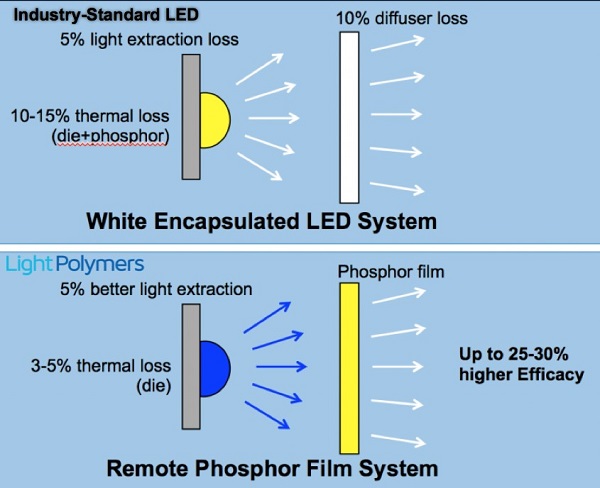

“Light Polymers' advanced polymer technology enables a different approach when compared to the typical fixed color encapsulated LED,” said Marc McConnaughey, CEO and President of Light Polymers during an exclusive interview with LEDinside. “Down-conversion is not a new concept to the LED industry, but implementation and cost issues have kept it from being adopted in volume lighting applications.”

Previously, high Color Rendering Index (CRI) lighting has been relegated to markets demanding extremely accurate color, such as art museums. Light Polymers lyotropic materials technology enables comfortable, well-distributed lighting that maintains full-color volume (High CRI) with less glare and no UV leakage. Since Light Polymers’ chemistry lowers manufacturing costs, these exceptionally high-quality lighting products will be available at an affordable price that beats the market competition.

|

|

(Light Polymers/ LEDinside) |

“Light Polymers’ technology consists of lyotropic materials with certain unique properties. These properties cause the phosphor particles to be packed very tightly together, maximizing the blue light conversion,” explained Light Polymers’ Dr. Jacky Huang. “This allows the use of any low to mid power blue LED without expensive binning or sorting operations, as well as eliminating the expensive, heavy heat sinks associated with high brightness LEDs, both which add extra costs. The result is lighting with minimum color shift and less lumen drop at a lower power consumption than traditional encapsulated LED lighting.”

Affordable High CRI LED Downlights: A Niche Market

Carving a niche in the crowded LED downlights market, Light Polymer’s Crystallin downlights, one of the thinnest on the market, offer museum-quality lighting for everyday use at an affordable price, either at home or for business.

“We can make any spectrum precisely within a few days. We will introduce a custom spectrum service to the market through which we will prepare and deliver a phosphor film of any desired spectrum based on client needs. We know that downlights are a cost sensitive, high volume market, yet we believe there is a demand for very high CRI downlights at an affordable price,” saidBryan Chang, Vice President of Light Polymers.

Light Polymers is bringing to market the Crystallin Gold™, a 6” downlight at 98+ CRI for both 3,000 and 5,000K color temperatures, at $14.99 (US) MSRP. In the 6” downlight form factor, Light Polymers will also offer the Crystallin Red™ (composed of a light spectrum that does not affect sleep), Crystallin Orange™ (for light sensitive applications such as semiconductor fabs and programmers who like to code in orange light), Crystallin Salon™ for beauty and nail salons and Crystallin Grow™ (an indoor grow light for plants).

In addition, Light Polymers will offer Crystallin Custom™ - a service through which customers can order any specific lighting spectrum. Light Polymers is also working on multilayer films that can boost lumen efficiency by up to 30% or more over traditional lighting.

“We believe that the efficiency of current LED design has reached a plateau and that the key to increasing total efficiency further is to bring more efficient optics to market,” described McConnaughey.

|

|

Crystallin Gold Downlight (Light Polymers/ LEDinside) |

LED Horticultural Lighting: A Booming Business

The horticultural grow light market presents a lucrative opportunity for LED lighting manufacturers. LEDinside expects the global LED horticultural lighting market to grow from (US) $576 million in 2016 to around (US) $1.42 billion by 2020.

“Light Polymers' chemistry enables low-cost LED down-conversion and a different way to make grow lights,” said Marc McConnaughey. “All current LED manufacturing methods still fall short in their ability to make and deliver precise spectra on-demand, with short production lead times. Our grow lights are for vertical farmers who are looking to optimize their farms for maximum efficiency and PPFD while decreasing energy costs for both lighting and air conditioning. We can offer any precise growth spectrum on demand by using our down-conversion technology and simple, low-cost blue LEDs.”

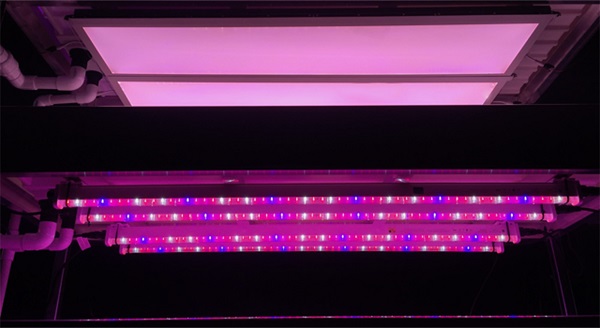

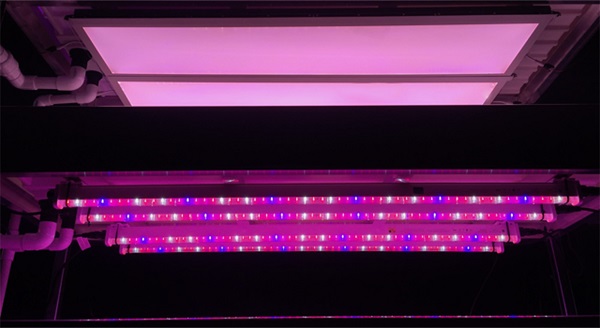

Light Polymers will soon introduce the GrowBlade™ family of flat-panel down-conversion grow lights in four sizes, 300x300mm, 300x600mm, 300x1200mm, and 300x1500mm. GrowBlades are designed for indoor farmers who need fixed spectrum combined with low capital and operating costs. The high efficiency of these lights ensures cool operation. Combined with the evenly diffused light from the Crystallin film and a thin 3cm form factor, GrowBlades allow more growing levels in the same footprint, increasing productivity for vertical farming operations. The wide-area diffused light also combines with specially designed Crystallin Grow film spectra for improved light quality and crop yields. Early field tests are demonstrating that a single GrowBlade can replace 2 to 3 bars of multiple-color encapsulated LEDs.

|

|

Light Polymers field-test GrowBlade lights (top) versus bar-type grow lights using multiple single-frequency LED emitters. (Light Polymers/ LEDinside) |

The continued international legalization of both medical and recreational marijuana is also expected to spur global LED grow light demand. Light Polymers aims to capitalize on this niche lighting market with groundbreaking grow light with unique top and side lighting that maximizes the flower growth.

|

|

GrowBlade lights with Crystallin Grow film for vertical farming. (Light Polymers/ LEDinside) |

Red-Light Therapy for Beauty Care

In addition to LED downlights and horticultural grow lights, Light Polymers will be launching a red-light therapy beauty care product line this fall. Using low-cost blue LEDs, Light Polymers’ advanced down-conversion films are capable of delivering therapeutic red light at a much lower cost than previous technologies. Light Polymers has recently demonstrated a red-light therapy film on 660nm.

“Lyotropic materials enable many high-performance specialty applications at everyday pricing,” said Holly Yeh, Business Development leader for Light Polymers Asia. “Light Polymers has requests from high-end hotels who want to offer in-room red-light therapy to their guests.”

Red-light therapy is approved by the Food Drug Administration (FDA) for use in the U.S. NASA research studies showed red-light effective at relaxing muscles, rebuilding collagen to reduce wrinkles, and repairing sun damage. The final products will come in at 300x600mm and 300x1200mm form-factors, encased with a modern consumer electronics industrial design.

CN

TW

EN

CN

TW

EN