Shin-Tson Wu, a Pegasus Professor at the University of Central Florida College of Optics and Photonics, holds several prestigious titles, including Academician of Academia Sinica, founding member of the National Academy of Inventors in the US, as well as Fellow of IEEE, OSA, SID, and SPIE. Wu is also one of the first six inductees into the Florida Inventors Hall of Fame. In academic research, Wu has long been dedicated to the field of AI-assisted AR and VR near-eye displays, with his research encompassing optical engines, optical systems, and advanced display materials. Wu’s academic achievements are outstanding, with numerous publications to his name, and holds 105 US patents, some of which have been widely applied in commercial products, including the LCoS displays used in the recently launched smart glasses by Meta. TrendForce had the honor to invite Wu for a conversation to share his insights on the development of near-eye display technology from an academic perspective.

Regarding AR display light sources, Wu pointed out that both LEDoS and LCoS come with respective advantages and areas for improvement. LEDoS technology benefits from the advantage of optical engine miniaturization, and performs excellently in low average pixel lit (APL) scenarios, such as information prompts. However, thermal issues would emerge once the APL exceeds 20%, thereby resulting in reduced peak brightness for LEDoS. Additionally, central chip cooling is challenging, which leads to temperature non-uniformity, thus degrading color uniformity, as well as resulting in lower light efficiency and red color shifting. Conversely, LCoS technology, which operates using the field sequential color method, performs stably in high APL applications. However, in low APL scenarios, it is prone to highlighting chip edge defects and light leakage, thus yielding the "gray border" phenomenon. Fortunately, this can be mitigated through Mini LED local dimming. Additionally, since LCoS is a passive light source system, it requires additional polarization adjustments, which generate in a larger optical engine size compared to monochromatic LEDoS. To address these challenges, both the academia and industry are focusing on developing miniaturization techniques for LCoS optical engines and increasing their optical efficiency to overcome size limitations and reduce power consumption.

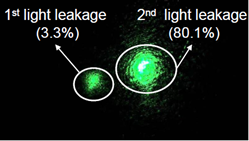

Gray Frames of LCoS (Source: Meta)

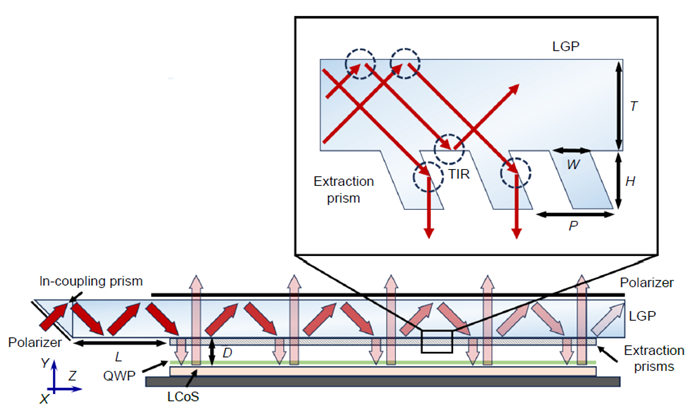

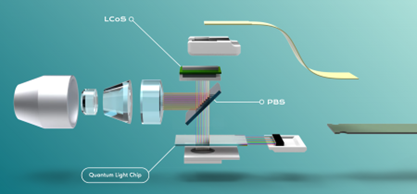

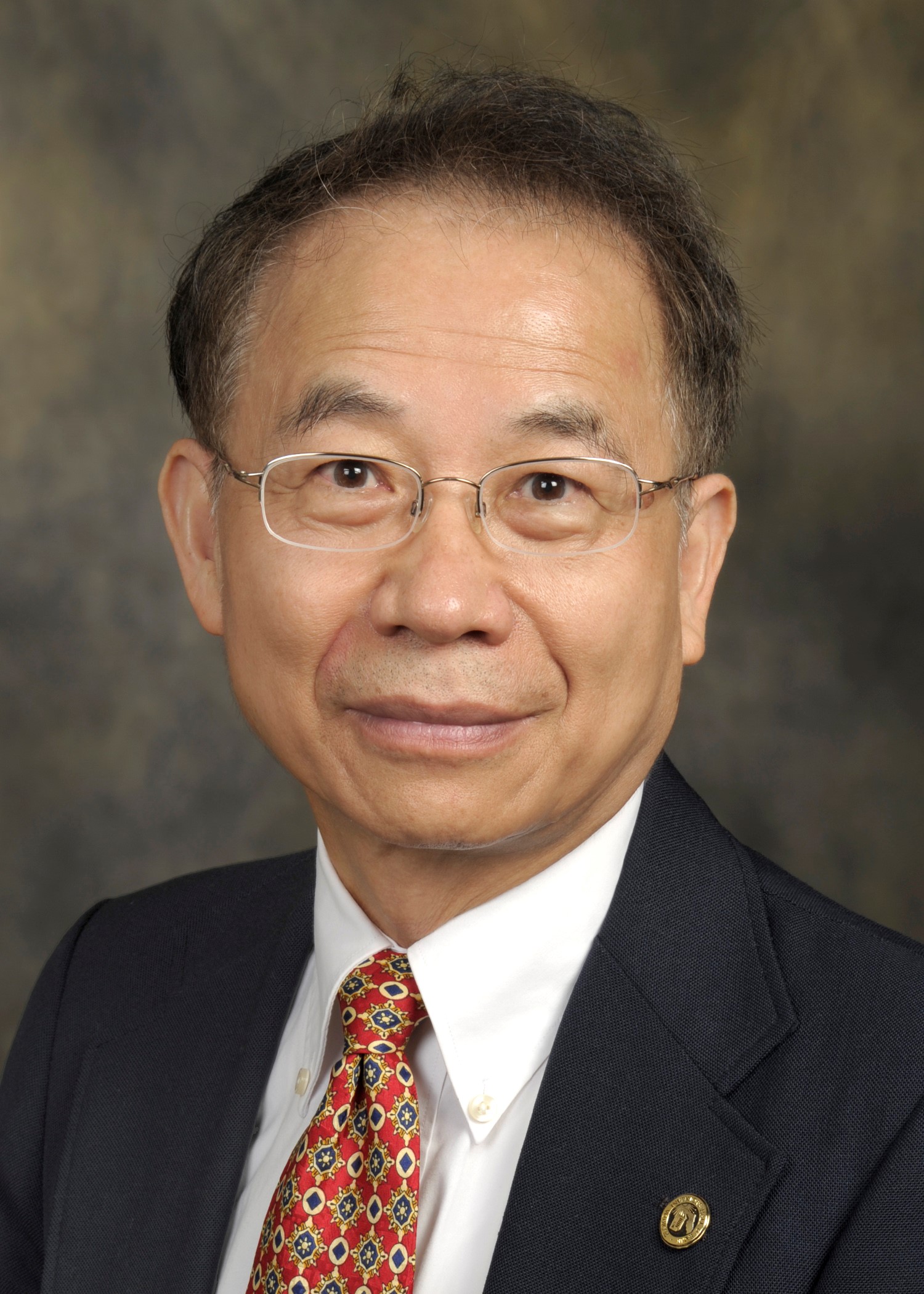

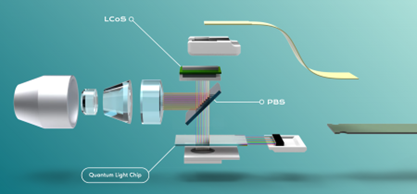

In addition to the miniaturization technique for LCoS mentioned from the previous exclusive interview with Himax Display, which used a flat Polarization Beam Splitter (PBS) system for Front-Lit LCoS, Wu’s team at UCF also proposed two LCoS design structures in 2024. One of these designs has proposed an alternative PBS-type approach that uses a combination of 4 PBSs and two half-wave plates to form an arrayed LCoS system. This dual-sided light entry system allows light to enter from both the left and right sides, undergoing two splitting processes before exiting. Such design is expected to reduce the volume to 25% of traditional structures. The other one was detailed in the journal (US Patent 12,436,333), where the UCF and Meta team introduced an LCoS design that does not require a PBS, but instead uses a Light Guide Plate (LGP) coupled with an Extraction Prism system. This technology leverages the Total Internal Reflection (TIR) mechanism to confine light transmission within the LGP, and then efficiently extracts the light through the TIR mechanism on the Extraction Prism. To achieve uniform illumination on the LCoS, light is systematically extracted as it propagates through the LGP, meaning that the light flux is depleted over its path. Therefore, Extraction Prisms with different aperture ratios need to be designed. The final volume of the LCoS module (4.4µm pixel pitch and 1024x1024 resolution) is estimated to be only 0.25 cc.

PBS Array LCoS System of the UCF Team

LGP + Extraction Prism Co-Developed by Teams at UCF and Meta

Currently, most LCoS optical engines use LED or Mini LED as the backlight source. However, Wu, during this exclusive interview, highlighted a noteworthy LCoS manufacturer, VitreaLab, whose technology features the use of "laser diodes" as the backlight source. Due to the exceedingly small beam spot of the laser, complex optical path designs are required for multiple beam expansions, thereby significantly complicating the overall design and manufacturing of overall optical systems compared to that of LED sources, which explains the lesser degree of adoption within the industry. However, VitreaLab has successfully transformed the previously complex optical paths into a quasi-2D structure by designing 3D channels on low-loss glass waveguides, which simplified the design, and achieved local illumination to reduce power consumption of products. VitreaLab, at the same time, also incorporated MEMS mirror architecture to address the common speckle problem associated with laser backlighting. The advancement of laser-backlight LCoS is going to be highly promising, should overall architectures achieve further miniaturization in the future.

VitreaLab’s Laser Backlight LCoS

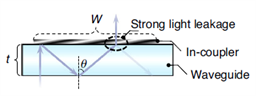

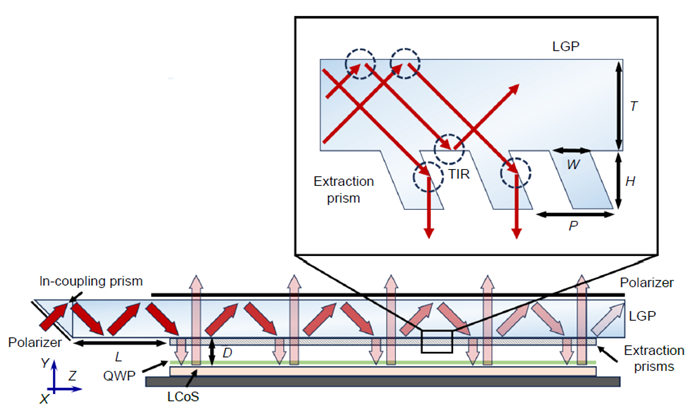

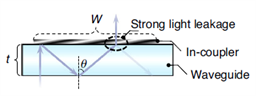

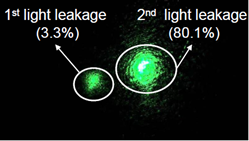

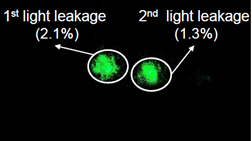

In the field of waveguide technology, Wu has highlighted that surface relief gratings (SRG) often face limitations at the in-coupler due to factors such as coupling width and the angle of incidence. These limitations can result in significant light leakage, with light loss reaching up to 83%, and frequent occurrences of ghost images. By replacing the in-coupler with a polarization volume grating (PVG), its polarization characteristics can effectively eliminate ghost images and enhance efficiency to twice that of SRG, as noted in the journal Light: Science & Applications and US Patent 12,455,458.

However, the manufacturing technology for PVG is not yet fully mature. When used with a full-color optical engine, differences in diffraction angles due to varying RGB wavelengths typically require a dual-layer PVG structure for effective light coupling. Although current technologies can achieve single-layer full-color displays, they often result in a relatively narrower FoV. To overcome this challenge, Wu has proposed an ideal solution: a hybrid structure that uses PVG at the in-coupler and SRG at the out-coupler. This approach combines the low stray light and high efficiency of PVG with the single-sheet full-color advantage of SRG, resulting in superior display performance and lighter products.

Multiple Interactions at In-Coupler of SRG Waveguide Lead to Light Loss

Comparison of Light Leakage Before and After Optimization of PVG In-Coupler

In summary, the interview with Wu outlines a roadmap for the evolution of near-eye display technology. Whether through innovative optical structures that minimize the volume of LCoS or through the use of hybrid waveguides to address efficiency and ghosting issues, these forward-looking technologies illuminate a clear path toward the ultimate goals of lightweight, high brightness, and low power consumption for AR glasses.

Author: Estelle / TrendForce

TrendForce 2025 Near-Eye Display Market Trend and Technology Analysis

Publication Date : 8/29, 2025

Language : Traditional Chinese / English

Format : PDF

Page Number: 168

|

If you would like to know more details , please contact:

|