SORAA Chief Technology Officer (CTO) Mike Krames sheds light on U.S. Department of Energy’s latest MR 16 CALiPER report and the impact of lumens on lighting.

The U.S. Department of Energy (DOE) has done a great deal to spearhead the solid-state lighting revolution, including significant funding for research, product development, and manufacturing. In addition, it provides useful programs to help educate and inform stakeholders in the industry, from manufacturers to designers to end users. One such endeavor is DOE’s Commercially Available LED Product Evaluation and Reporting (CALiPER) program, an honest-broker approach to making sure manufacturers measure up to their product performance claims.

Recently, CALiPER issued a report on MR16’s (no doubt of interest to this writer), which was highlighted last week in DOE’s most recent SSL Postings. While the report is thorough and contains very relevant and up to date information, I was dismayed at the lack of attention to the single most important metric of an MR16 (or any direct lighting) lamp, that is, peak luminous intensity (or center-beam candle-power, CBCP). This key performance metric is not about how much total light is produced (lumens), but rather how well the light produced is directed, which is what is important when one wants to illuminate a specific scene or object. For any given beam angle (determined by the lighting design), you simply want the highest intensity for the lowest electrical power, and lowest total amount of light, or lumens.

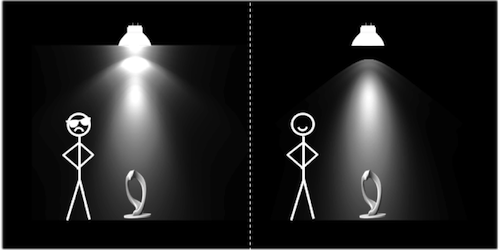

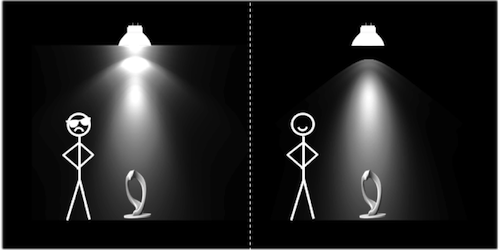

That’s right, in a directional lighting application with a given peak intensity, extra lumens are not beneficial, but are in fact a detriment. In the comparison of two lamps with the same beam waist and CBCP, the one with more lumens is in fact the lower performing lamp. The extra lumens are not contained in the main beam (defined by the beam half-power angle) but are in the “spill” of the lamp, leading to unwanted illumination, washed-out scenes, and glare (see figure below).

|

|

Both lamps have the same beam width and intensity (CBCP), but the one on the left has significantly higher lumens, and thus glare. (All images courtesy belong to SORAA) |

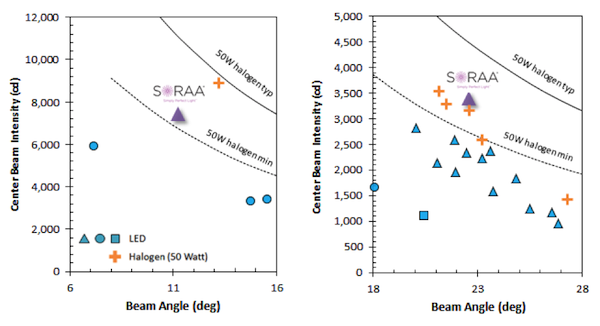

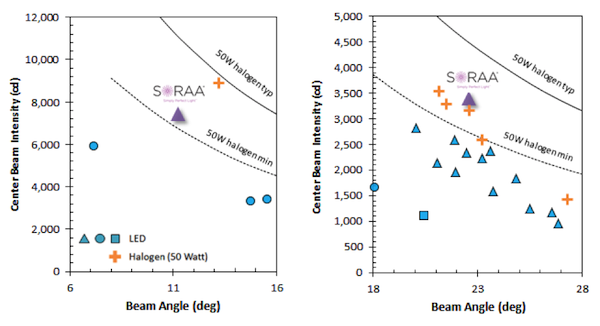

The solid-state lighting industry’s blind allegiance to the lumen as the be-all and end-all metric encourages the development of directional lamps that, frankly, blind end users(!). The recent CALiPER report is symptomatic of this, primarily focusing on lumens. While it did include a chart on the key metric, peak luminous intensity or CBCP, it was displayed in a way that made it very difficult to clearly compare the MR16 products on this basis. Below, I show the CALiPER report’s data for spot (6 to 16 degree beam width) and narrow-flood (18 to 28 degree beam width) lamps for more clear comparison. The results are striking: not one of the LED MR16 lamps meets the minimum 50-Watt halogen equivalency level, except for Soraa, despite myriad product package claims.

|

|

U.S. Department of Energy’s CALiPER report data on LED MR16 lamp performance (June 2014). Of all the lamps tested, only Soraa products exhibited performance that exceeded the minimum for 50 Watt halogen. |

It’s no secret that the MR16 is one of the toughest form factors for LEDs, due to its small form factor and tight beam control requirements. It’s the reason that Soraa chose this platform for our first product and demonstration of the unique benefits of GaN-on-GaN technology. And we have not stopped here, but have recently expanded our product portfolio to a wider range of direct lighting solutions, including PAR and AR111 lamps, all of which utilize our Point Source Optics for well-controlled beam patterns and world-leading peak intensity capability.

DOE’s CALiPER and other benchmarking programs have greatly benefited the industry and are widely used and cited, but we must remember that lighting is complex, involving space and spectrum, and cannot be adequately described only by the ubiquitous “lumen”.