Mass transferring is one of the biggest obstacles for the mass production of Micro LED display technology. Many players in the industry have come up with different methods to solve the issue and it is also a focal point in the Micro LED Technology Research Contest, where several research papers targeted the topic.

The article submitted by Thomos Q. Ke has illustrated an idea to produce Micro LED without the process of mass transfer. The paper, titled “Mass Production Solution of Micro-LED without Mass Transfer” was awarded with an honorable mention in the contest.

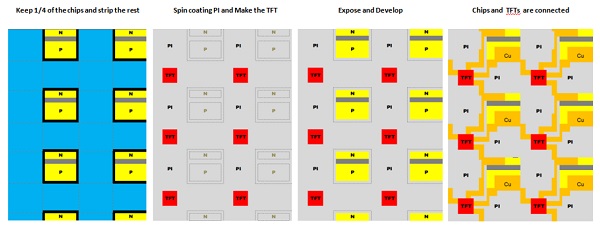

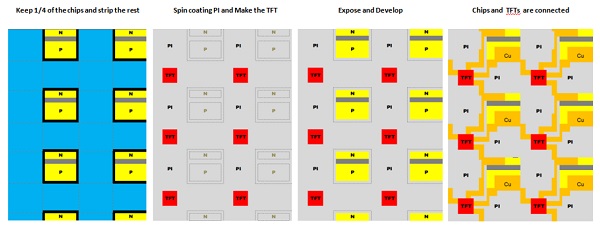

In the article, researchers proposed to redesign the process of Micro LED manufacturing and use the exiting processes to avoid mass transfer. With the proposed design, producers do not need to move Micro LEDs from the wafer substrate until the chips are packaged. Instead, the process removes three fourths of the epitaxial LED wafer on the substrate and uses PI to refill the opening part while placing TFT driver beside the remaining one fourth of the chip. With the process, producers can manufacture RGB Micro LED for displays without mass transferring.

(Image: Ke, 2018)

Judges have commented that the approach of integrating TFT with Micro LED by productizing active driver on LED array wafer is similar to those technologies of Lumiode, eMagin NthDegree and Osram. The difference of the research is that it gives up three fourths of the LED wafer to save spaces for RGB dies and TFT.

In order to save the cost and speed of mass transferring, the research chooses to spend more cost on the materials. The approach might be competitive for mass production before the technologies of mass transferring become more mature. Once the cost of mass transfer technology drops, the advantage of this method will no longer exist.

Full paper: //p.ledinside.com/led/2018-11/1541673102_83518.pdf