A team from Yokohama National University in Japan believes they have developed a method to obtain a sensor by taking advantage of slow light and published the results in the Optica, a journal published by The Optical Society, on January 2020.

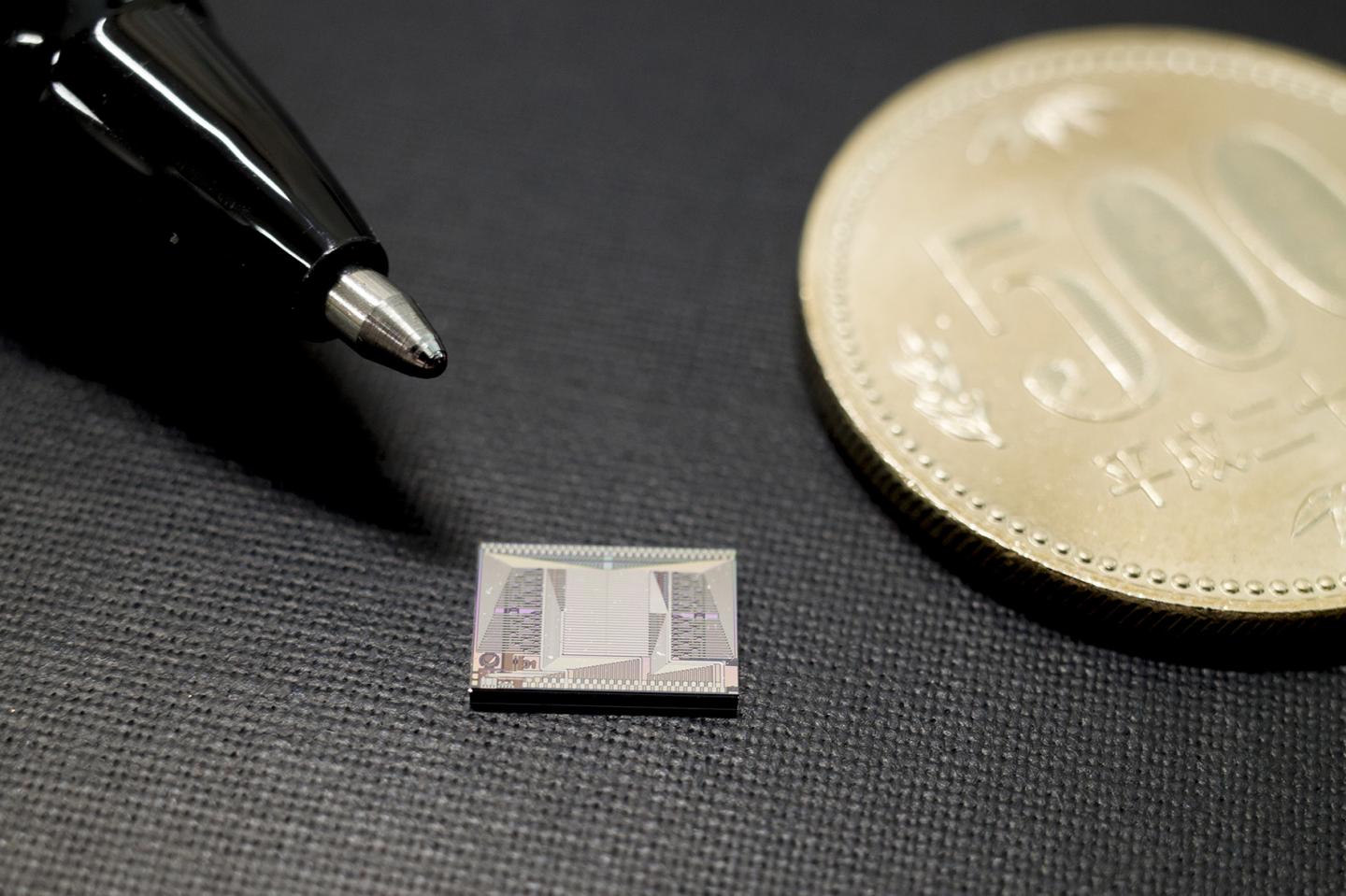

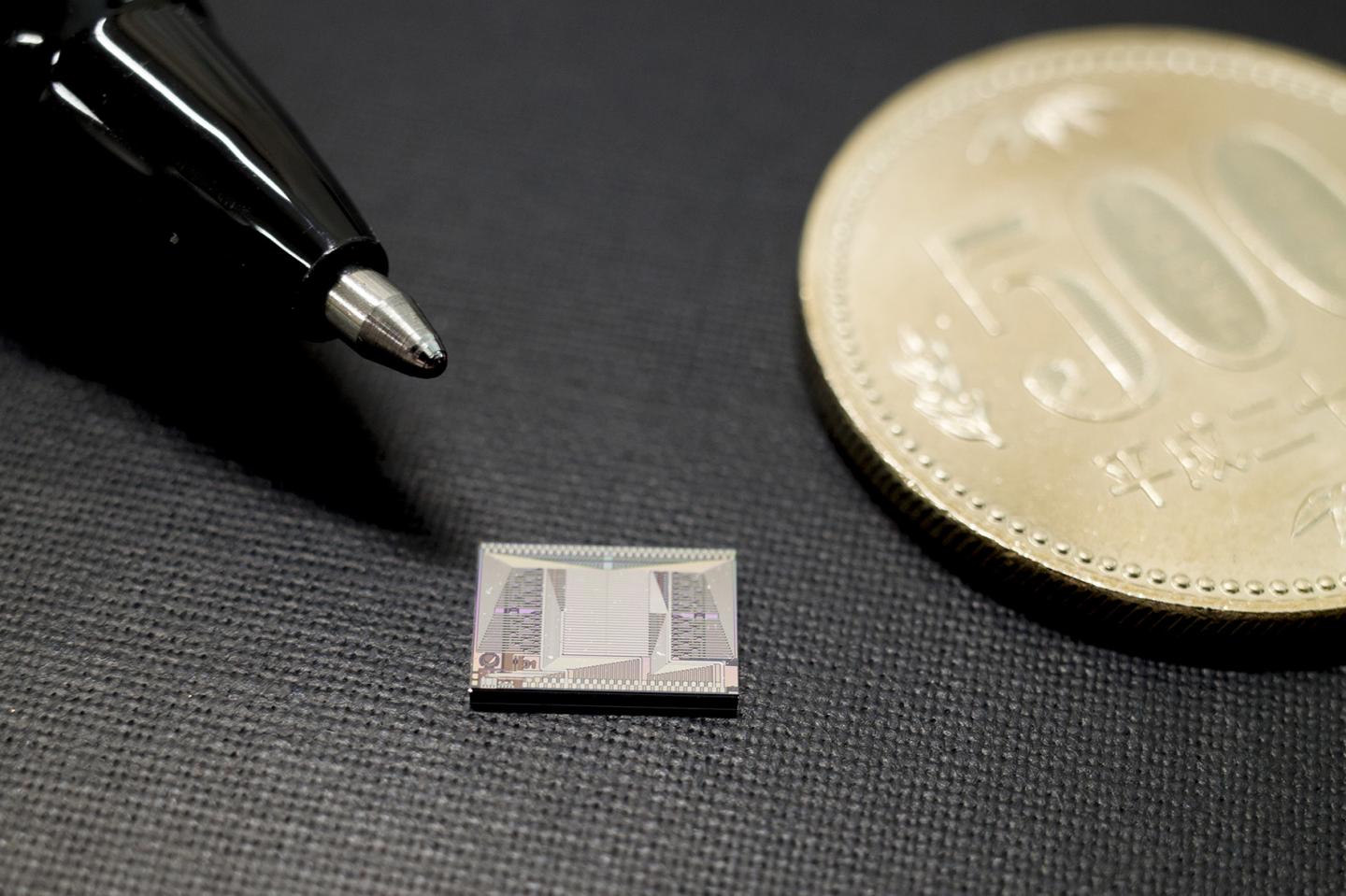

A small-sized silicon photonics chip that can be used for non-mechanical beam steering and scanning.

(Image: Yokohama National University)

In modern LiDAR sensors, many of the systems are composed of a laser source; a photodetector, which converts light into current; and an optical beam steering device, which directs the light into the proper location.

Toshihiko Baba, the author and professor in the Department of Electrical and Computer Engineering at Yokohama National University, noted that most of the optical beam steering devices are based on mechanics such as rotary mirrors, which makes the device large and heavy. The bulky designs usually have speed limitation and higher cost.

In recent years, according to Baba, more engineers have turned toward optical phased arrays, which direct the optical beam without mechanical parts. But, Baba warned, such an approach can become complicated due to the sheer number of optical antennae required, as well as the time and precision needed to calibrate each piece.

"In our study, we employed another approach, what we call 'slow light,'" Baba said.

Baba and his team used a special waveguide "photonic crystal," aimed through a silicon-etched medium. Light is slowed down and emitted to the free space when forced to interact with the photonic crystal. The researchers engaged a prism lens to then direct the beam in the desired direction.

With the new approach, the research team created a smaller and resilient LiDAR that can be produced in lower cost. The team plans to more fully demonstrate the potential of a solid-state LiDAR, as well as work on improving its performance with the ultimate goal of commercializing the device.