Micro LED has been seen as a revolutionary display technology and a popular keyword in the tech industry because of its high brightness, contrast and stability. Since Samsung’s announcement of The Wall in 2018, companies worldwide have been developing Micro LED products for various sectors. For example, Apple will reportedly introduce Micro LED to its smart watches in 2024. As Market research company TrendForce indicates, the use of Micro LED will be extended to AR glasses, smartphones and automotive displays with a widespread revolution in the offing.

Cost Is the Final Piece of the Puzzle for Commercialization

Over the past few years, Micro LED commercialization has been like an obstacle relay. Manufacturing procedures from chip production to mass transfer and to inspection and repair have formed a high cost threshold awaiting suppliers to overcome. According to TrendForce , there are two approaches to persuading the market to accept commercial Micro LED products: 1) lowering the chip cost and 2) proposing a solution that covers all the manufacturing processes from transfer to inspection. To achieve the latter goal, selecting appropriate semiconductor materials matters for process optimization in addition to breakthroughs in transfer technologies.

LEDinside hosted an exclusive interview with Heraeus Electronics, an advanced material supplier for the tech industry worldwide. During the interview, Hanwen Zhang, global product manager at Heraeus Electronics who specializes in advanced packaging solder materials, detailed how the company’s specially engineered solder pastes break through the existing limitations to Micro LED manufacturing and how they can help customers overcome cost challenges and ultimately achieve Micro LED commercialization.

“Mass transferring Micro LED dies to the target backplane during assembly has been an issue shared by our customers,” said Zhang. If Micro LEDs are not properly mounted to the target positions, defects might form, which will increase the cost of the subsequent inspection and repair process.

Solder pastes are essential for die bonding and transfer. As a solder paste supplier, Heraeus has been developing products exclusively for Mini/Micro LEDs and rolled out the state-of-the-art Welco LED101, a no-clean paste featuring self-alignment. The product enables accurate die attach, which can largely improve manufacturing process, enhance the yield rate and accelerate productivity, thereby helping customers reduce production costs.

Welco LED101 Boosts Mini/Micro LED Transfer Performance by Overcoming Equipment Limitations

To transfer millions of Mini/Micro LEDs to the target substrate accurately and quickly, manufacturers have proposed various novel technologies including laser transfer, fluid assembly and roll transfer. No matter which method is adopted, whether the transferred dies can be desirably bonded is a key factor affecting the yield rate.

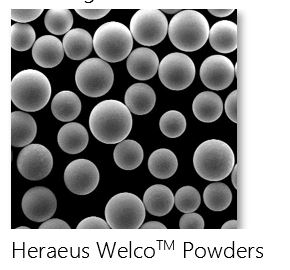

When specifying the technical requirements of solder pastes for die bonding, Zhang explained, “Because Mini/Micro LEDs are extremely small, printing pastes used during the large-area die bonding process must have a small powder size, too.” If only a flux is used to attach Mini/Micro LEDs to the target substrate, the LED dies will easily fall off during reflow, resulting in defects. Therefore, solder paste is still a better solution for the said process. However, it is extremely challenging to make ultra-fine pitch solder powders (T6, T7 & beyond) with consistently high yield and quality, as powder surfaces tend to be rough after sieving and prone to oxidation, causing voids when the paste is subjected to reflow.

Heraeus’ patented technology WelcoTM enables accurate control of parameters for the production of ultra-small solder powder with a perfectly smooth surface, spherical shapeand narrow particle size distribution. The powder ensures stability and reliability of the produced solder paste, allowing Mini/Micro LEDs to be soldered reliably onto a PCB or glass substrate with zero defects.

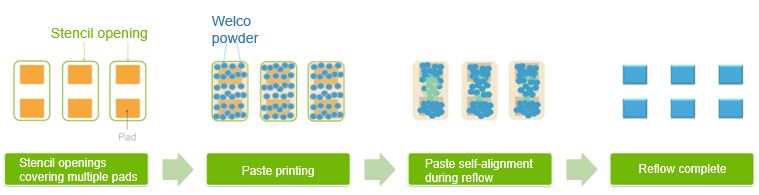

Despite the said ultra-fine powder technology, commercially available printing stencils are incompatible with such a small chip size setting (i.e., Micro LED). Therefore, Heraeus rolled out the self-alignment Welco LED101 solder paste. This product is applicable to Micro LED die bonding without the need of the finest powder, thereby overcoming the existing limitation for stencil manufacturing.

Zhang indicated, “Even if the individual aperture on a stencil covers multiple pads of Micro LEDs, the Welco LED101 paste will automatically self-align to the pads after reflow, forming reliabile solder joints without bridging ”. This unique self-alignment property makes solder paste printing possible with the existing stencil technologies for mini & microLED dies.

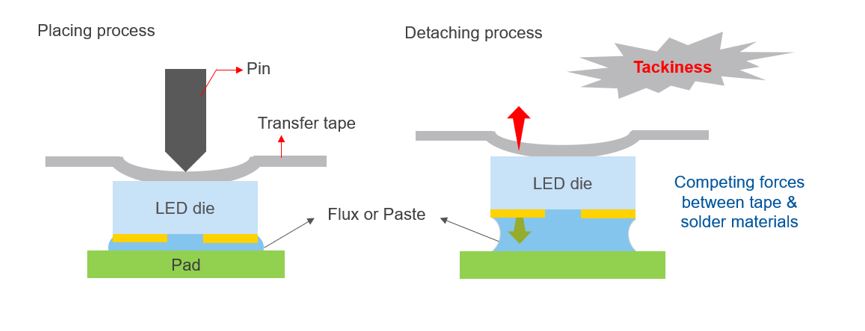

Welco LED101 is designed to possess high tackiness needed in miniLED tape transfer and microLED laser transfer technologies, which are two common methods adopted by most manufacturers.. In the tape transfer process, LED dies must be released from the sticky transfer tapes onto the substrates, which requires the solder material to be tacky. High tackiness is also preferred in laser transfer processes where the dies are released from carriers by laser.

“Our customers’ testing data show that the die missing ratio can be as high as 20% if a conventional solder paste is used. When adopting the Welco LED101, the number drops to near-zero level,” Zhang specified. The said numbers have highlighted the importance of selecting an appropriate solder paste for the optimization of Mini/Micro LED mass transfer.

Metal Material Recycling for Technological Sustainability in the Future

In addition to giving a boost to Mini/Micro LED commercialization, Heraeus has noticed that the entire industry is moving towards product miniaturization. Under such circumstances, the Welco technology is also the ideal solution for untra-fine pitch packages in the semiconductor industry.

With respect to global tech industry outlook, Zhang emphasized the company’s focus on issues related to sustainable development. “Heraeus has begun using 100% recycled tin and gold to make products with an effort to reduce the environmental impact caused by metal mining as much as possible,” he added. Specifically, The Welco Type 6 and Type 5 pastes made of 100% recycled tin have entered mass production with equivalent efficiency and performance, but potentially up to 800 times less carbon emissions than their counterparts produced using newly mined metals .

As Apple, Google and other tech giants have pledged to reach net zero emissions by 2030 and requested their suppliers to use recycled resources, Heraeus expects recycled metal products to become the top choice for supply chains to achieve sustainable development.