Starting to invest in the development of Micro LED equipment in 2017, Contrel believes that the decision was right after looking back at the then product development strategies today (2023). TrendForce was honored to invite Chih-Hao (Kevin) Tsai, director at Contrel, to talk about the company’s Micro LED mass transfer and repair technologies as well as their advantages.

The existing stamp transfer works through thermal pressure release using PDMS adhesives. As Tsai indicated, Contrel has been aiming at largely simplifying the manufacturing process of Micro LED displays as early as when it started developing mass transfer and repair technologies. The laser-induced transfer bonding (LITB) technology proposed by Contrel does not require additional materials and other manufacturing equipment. The technology enables simultaneous Micro LED mass release and bonding within a very short period of time (<1 ms). Compared to laser-induced forward transfer solely providing laser release announced by its competitors, LITB can save a large amount of adhesives / carrier material costs as well as AOI inspection and manufacturing time. The transfer area measures 65x65mm with precision being limited at ±1.5µm. The equipment provider is now developing equipment enabling the manufacturing of a 4K2K displays within 30 minutes (UPH = 50KK).

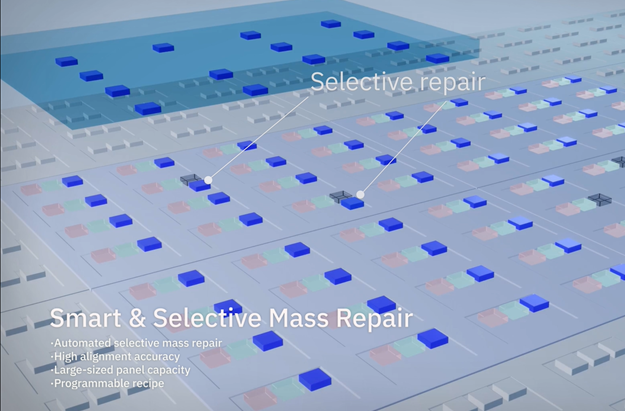

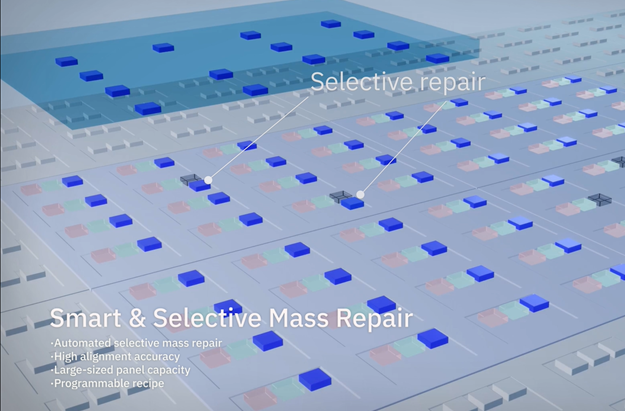

Smart & Selective Mass Repair (SSMR)

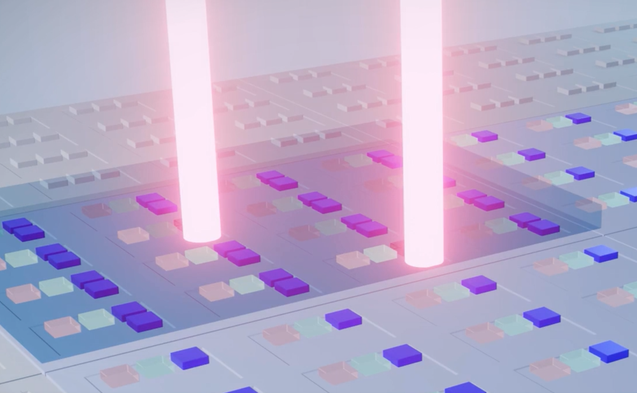

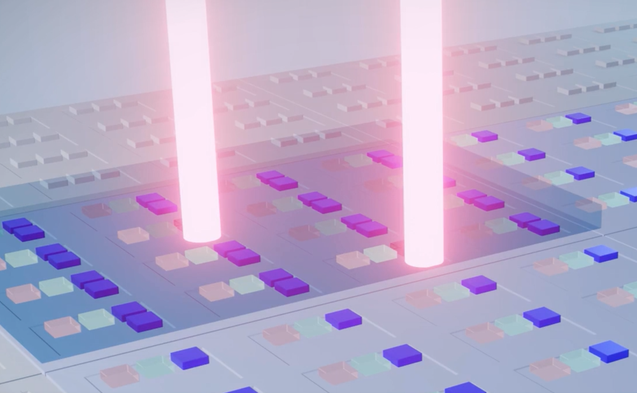

Regarding Micro LED defect repair, Contrel has integrated the existing AOI and AI technologies to self-develop the Smart & Selective Mass Repair (SSMR) platform, allowing its customers to effectively cut Micro LED repair time and achieve a final repair yield of >99.999% through laser bonding.

Random and Simultaneous Repair of Multiple Micro LED Defects

The Contrel equipment comes with IR lasers, which can guarantee the integrity of LEDs during transfer and repair. The equipment is compatible with chips measuring 5x5, 10x20, and 15x30µm, with target applications including large-sized displays (Video Walls / TVs), automotive displays, and wearable display devices.

1. Stamp Head: 1x1cm- 10x10cm (Depending Epi Wafer Size)

Author: Joanne / TrendForce

TrendForce 2023 Micro LED Market Trend and Technology Cost Analysis

Release Date: 31 May / 30 November 2023

Language: Traditional Chinese / English

Format: PDF

Page: 160 / Year

【Early Bird Discount】Micro LED: Metaverse X Technological Evolution X Application Innovation

Time:September 5th, 2023

Venue:Room 401, National Taiwan University Hospital International Convention Center, Taipei, Taiwan.

Price:Early Bird Discount USD 220 (until July 5th, 2023, the original price is USD 280)

|

If you would like to know more details , please contact:

|