2019-06-25

2019-06-25

Micro LED technology is on its way of business transforming! Since last year, we have seen different Micro LED display products in various trade shows from worldwide companies. Although Micro LED technology is still fraught with myriad challenges, it has become much more developed than it was two years ago. Schedules for the commercialization of Micro LEDs will unfold as the technology matures, predicted to bring Micro LED market revenue up to US$4.2 billion by 2023.

This year, LEDinside Micro LEDforum 2019 has invited professionals across the world to sha...

Continue reading →

2019-04-22

2019-04-22

Micro LED start up VerLASE announce that it is developing unique technologies for massively parallel assembly of Micro LED dies or films to address the major challenge of Micro LED display mass production. VerLASE, a spin-off of Versatilis, aims to develop novel technology of color conversion layers for Micro LED display. The company focused on practical methods with semiconductor and MEMs industry methods and existing tools in novel ways to enable deterministic, massively parallel transfers of Micro die, yet with provisions that allow selective repair. A...

Continue reading →

2019-02-13

2019-02-13

According to LEDinside’s 2019 Micro LED Next Generation Display Key Technology Report, Micro LED possesses excellent features no matter in high brightness, high contrast, high response time and power saving, which are all better than LCD and OLED. With Micro LED, various applications, such as watch, mobile phone, automotive display, AR, VR, monitor, TV and large display will develop towards a higher level in the future. According to LEDinside, although Micro LED technology faces many challenges, compared with two years ago, the current technological progress has been much improved. The early patented technology has already appeared in the physical sample display machine. In the future, Micro LED’s commercialization will be driven by the growth of Micro LED technology. In addition, the manufacturing process of Micro LED is complex and the requirement becomes stricter. The raw materials, process consumables, production equipment, testing instruments and auxiliary fixtures used in the process require sophisticated specifications and relatively high precision.

Continue reading →

2018-12-14

2018-12-14

The “Micro LED Technology Research Contest” held by LEDinside has received numerous articles providing innovative and practical solutions to enhance the manufacturing of Micro LED during June 6th – September 10th, 2018. LEDinside was very excited to learn all these novel ideas and technologies offered by different institutes and companies from all over the world. Selecting the winning articles was a tough task as most of them have proposed unique perspectives on how to solve the mass transfer issue of Micro LED or improve their yield rate.

Continue reading →

2018-11-13

2018-11-13

The Micro LED Technology Research Contest has received papers targeting all aspects of Micro LED technology development. Aside from mass transferring and methods for full color display, backplane is also a critical factor in the manufacturing process of Micro LED.

Continue reading →

2018-11-09

2018-11-09

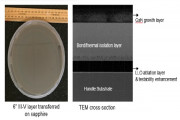

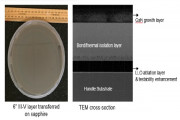

Veeco Instruments and ALLOS Semiconductors have continued their collaboration in developing GaN-on-Si epitaxy wafer for Micro LED production. The two companies have partnered to demonstrate the reproducibility of ALLOS’ 200 mm GaN-on-Si epitaxy wafer technology on Veeco’s Propel® MOCVD reactor.

“To bring Micro LED technology into production, simply presenting champion values for a single metric is insufficient. It is essential to achieve the whole set of specifications for each wafer with excellent repeatability and yield,” ...

Continue reading →

2019-06-25

2019-06-25

2019-04-22

2019-04-22

2019-02-13

2019-02-13

2018-12-14

2018-12-14

2018-11-13

2018-11-13

2018-11-09

2018-11-09