According to LEDinside’s 2019 Micro LED Next Generation Display Key Technology Report, Micro LED possesses excellent features no matter in high brightness, high contrast, high response time and power saving, which are all better than LCD and OLED. With Micro LED, various applications, such as watch, mobile phone, automotive display, AR, VR, monitor, TV and large display will develop towards a higher level in the future. According to LEDinside, although Micro LED technology faces many challenges, compared with two years ago, the current technological progress has been much improved. The early patented technology has already appeared in the physical sample display machine. In the future, Micro LED’s commercialization will be driven by the growth of Micro LED technology. In addition, the manufacturing process of Micro LED is complex and the requirement becomes stricter. The raw materials, process consumables, production equipment, testing instruments and auxiliary fixtures used in the process require sophisticated specifications and relatively high precision.

Micro LED technology bottleneck analysis

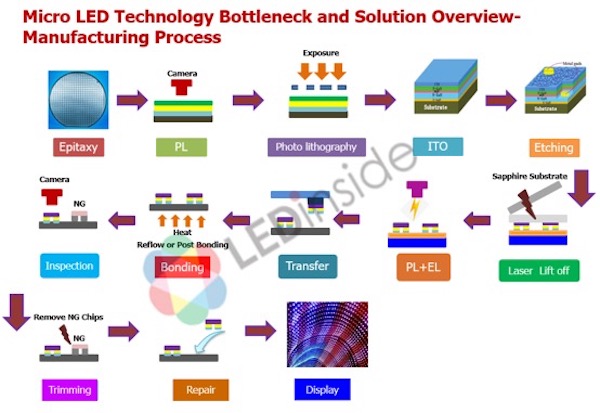

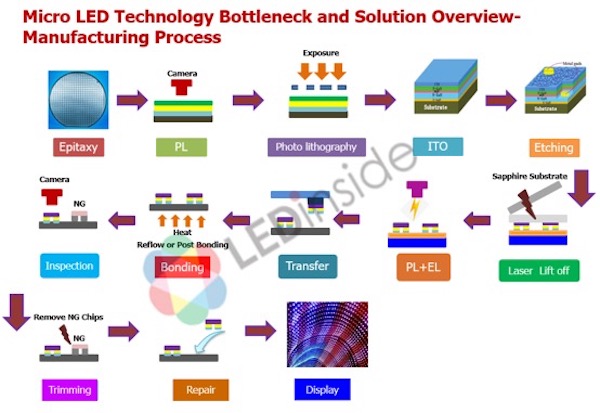

At present, there are nine bottlenecks, including epitaxy, chip, mass transfer, full color, bonding, power drive, backplane, inspection and repairing technologies. This research report will conduct in-depth discussion and analysis on the bottleneck of Micro LED technology.

Epitaxy Technology: At present, one of the challenges of Micro LED epitaxy technology is to improve wavelength uniformity and thickness uniformity. Thus, the wavelength will be more concentrated and the back-end inspection cost of epitaxy manufacturers can be greatly lowered. Besides, when LED chip is reduced to less than 100µm, the problem of unevenness caused by cutting damage around the LED chip may lead to electricity leakage and affect the overall luminous characteristics.

Chip Manufacturing Process Technology: Because of mass transfer manufacturing process, chips need to go through structural weakening in order to be picked up from the temporary substrate. In order to avoid the damage of chips during mass transfer manufacturing process, ALD process is required to protect and insulate the chips.

Mass Transfer Technology: Stamp pick & place technology can be applied to products greater than 10µm, but there may be problems for UPH and transfer equipment’s precision and stability. Fluidic assembly technology can be applied to products greater than 20µm. Although UPH can be increased, three transfer times are required to achieve full color. Laser transfer technology can be applied to products greater than 1µm, but the cost of laser equipment is high and will be a burden of initial investment.

Full Color Technical Solution: RGB chip color conversion solution confronts with problems like insufficient luminance efficacy and low yield in regard to technology of less than 20µm. Instead, quantum dot technology can fill this gap. However, some problems facing quantum dot solutions like coating evenness and reliability remain to be broken through.

Bonding Technology: Because Micro LED chip is too small, the large metal content of the solder paste can easily cause the p-pad and n-pad conduction of Micro LED to form a micro short circuit. Therefore, the adhesion technology will be a key challenge for Micro LED process. Currently, there are four directions: Metal Bump, Adhesive, Wafer Bonding and Micro Tube.

Driver Technology: In the active matrix drive array, each pixel is connected to the circuit and driven separately, which will allow Micro LED to operate at a lower current while maintaining brightness throughout the entire illumination time without significant loss of display brightness, but Micro LED drive current is extremely small, which makes the circuit design complicated and the space layout of drive power module will be denser.

Backplane Technology: There are four types: glass, flexible substrate, silicon substrate and PCB. At present, PCB backplane is the most widely used, mainly because of its high compatibility. The splicing can be used to meet various required sizes, and the corresponding substrate can be selected according to the requirements to be the corresponding backplane.

Inspection & Testing Technology: Micro LED application products use a large number of chips. Besides, the Photoluminescence and Electroluminescence of Micro LED module have to be detected correctly and rapidly. It is necessary to adopt mass testing method to reduce time and cost. Identifying good product quickly and accurately is a major problem in the manufacturing process and one of the main reasons for the bottleneck of current Micro LED testing technology.

Repairing Technology: In terms of Micro LED repairing solution, currently there are ultraviolet irradiation repairing technology, laser welding repairing technology, selective pick repairing technology, selective laser repairing technology and redundancy circuit design solution.

In January 2019, LEDinside has analyzed the key technologies of 2019 Micro LED next generation display. For more information, please call or email us. Thank you!

LEDinside 2019 Micro LED Next Generation Display Key Technology Report

Release Date: January 31, 2019

Format: PDF

Language: Traditional Chinese / English

Pages: 219

Quarterly Update: Micro / Mini LED Market Perspective Analysis - Vendor Dynamics, New Technology Import, Display Week / Touch Taiwan Direct Strike (March, June, September 2019; Approx. 10-15 pages/quarter)

Chapter 1 Definition and Market Scale of Micro LED

Product Definition of Micro LED

Analysis and Prediction of Micro LED Market Value

Analysis and Prediction of Micro LED Output Volume

Estimation of Micro LED Display Penetration Rate

Chapter 2 Micro LED Applications and Technology Development

Micro LED Product Overview

Micro LED Product Specifications Overview

Micro LED Applications- Specifications of Head Mounted Device

Micro LED Applications- Cost of Head Mounted Device

Micro LED Applications- Shipment Volume of Head Mounted Device

Micro LED Applications- Specifications of Wearable Device

Micro LED Applications- Cost of Wearable Device

Micro LED Applications- Shipment Volume of Wearable Device

Micro LED Applications- Specifications of Handheld Device

Micro LED Application- Cost of Handheld Device

Micro LED Application- Shipment Volume of Handheld Device

Micro LED Application- Specifications of IT Device

Micro LED Application- Cost of IT Display

Micro LED Application- Shipment Volume of IT Device

Micro LED Application- Specification of Automotive Display

Micro LED Application- Cost of Automotive Display

Micro LED Application- Shipment Volume of Automotive Display

Micro LED Application- Specifications of TV

Micro LED Application- Cost of TV

Micro LED Application- Shipment Volume of TV

Micro LED Application- Specifications of LED Display

Micro LED Application- Cost of LED Display

Micro LED Application- Shipment Volume of LED Display

Chapter3 Micro LED Patent Analysis

2000-2018 Micro LED Patent Layout- Patent Family Analysis

2000-2018 Micro LED Patent Layout- Region Analysis

2000-2018 Micro LED Patent Layout- Technology Analysis

2000-2018 Micro LED Patent Layout- Manufacturer Analysis

2001-2018 Micro LED Patent Layout- Mass Transfer Technology Patent Family Analysis

Mass Transfer Technology- Patent Technology Overview

Mass Transfer Technology- Patent Technology Classification

2001-2018 Micro LED Patent Layout- Mass Transfer Technology Patent Family Analysis

Mass Transfer Technology- Brand Manufacturer Technology Layout Analysis

Mass Transfer Technology- Start-up and Research Institution Technology Layout Analysis

Chapter 4 Micro LED Technology Bottleneck and Solution

Micro LED Industry Technology Overview Analysis

Micro LED Technology Bottleneck and Solution Overview- Manufacturing Process

Micro LED Technology Bottleneck and Solution Overview- LED Epitaxy and Chip Manufacturing Process

Micro LED Technology Bottleneck and Solution Overview- Transfer Technology/Bonding Technology/Drive and Backplane Technology

Chapter 5 Epitaxy Technology Bottleneck and Challenge Analysis

Epitaxy Technology- Solution

Epitaxy Technology- Epitaxial Wafer Structure and Light Emitting Principle

Epitaxy Technology- Epitaxy Emissive Layer Material and Luminous Efficacy

Epitaxy Technology- The Leakage Problem of Chip Miniaturization Causes the Drop of Luminous Efficacy

Epitaxy Technology- Equipment Technology Classification

Epitaxy Technology- Equipment Technology Comparison

Epitaxy Technology- Epitaxial Wafer Key Technology Classification

Epitaxy Technology- Epitaxial Wafer Key Technology Classification- Wavelength Uniformity

Epitaxy Technology- Epitaxial Wafer Key Technology Classification- Defect Control

Epitaxy Technology- Epitaxial Wafer Key Technology Classification- Increase of Utilization of Epitaxial Wafer

Epitaxy Technology- Applicability Analysis

Chapter 6 Chip Manufacturing Process Technology Bottleneck and Challenge Analysis

Chip Manufacturing Process Technology- Development of LED Chip Miniaturization

Chip Manufacturing Process Technology- LED Chip Production Process

Chip Manufacturing Process Technology- Structural Differences between Lateral Chip, Flip Chip and Vertical Chip

Chip Manufacturing Process Technology- Miniaturized LED Chip (Including Sapphire Substrate) Scribing Technology

Chip Manufacturing Process Technology- Miniaturized LED Chip (Excluding Sapphire Substrate) Scribing Technology

Chip Manufacturing Process Technology- Laser Ablation

Chip Manufacturing Process Technology- Structural Weakening and Insulating Layer

Chip Manufacturing Process Technology- Design of Structural Weakening

Chip Manufacturing Process Technology- Design of Transfer Head

Chip Manufacturing Process Technology- Differences between Traditional LED and Micro LED Chip Manufacturing Processes

Chapter 7 Mass Transfer Technology Bottleneck and Challenge Analysis

Mass Transfer Technology- Transfer Technology Classification

Mass Transfer Technology- Thin Film Transfer Technology Classification

Mass Transfer Technology- Thin Film Transfer Technology- Pick & Place Technology

Mass Transfer Technology- Thin Film Transfer Technology- Non-selective Pick Technology

Mass Transfer Technology- Thin Film Transfer Technology- Selective Pick Technology will Increase Wafer Utilization

Mass Transfer Technology- Thin Film Transfer Technology- Selective Pick Technology in Repair Application

Mass Transfer Technology- Thin Film Transfer Technology- Factors that Affect UPH

Mass Transfer Technology- Thin Film Transfer Technology- Solution of Increasing UPH for Large Transfer Head

Mass Transfer Technology- Thin Film Transfer Technology- Higher Transfer Head Accuracy Requirement

Mass Transfer Technology- Thin Film Transfer Technology- Comparison between Transfer Times and Wafer Utilization

Mass Transfer Technology- Thin Film Transfer Technology- Comparison between Cycle Time and UPH

Mass Transfer Technology- Thin Film Transfer Technology: Apple (LuxVue)

Electrostatic Adsorption + Phase Change Transfer

Mass Transfer Technology- Thin Film Transfer Technology: Samsung

Chip Transfer and Flip

Mass Transfer Technology- Thin Film Transfer Technology- Van der Waals Force Introduction

Mass Transfer Technology- Thin Film Transfer Technology: X-Celeprint

Van der Waals Force

Mass Transfer Technology- Thin Film Transfer Technology: ITRI

Electromagnetic Adsorption

Mass Transfer Technology- Thin Film Transfer Technology: Mikro Mesa

Adhesion and Reaction Force

Mass Transfer Technology- Thin Film Transfer Technology: AUO

Electrostatic Adsorption and Reaction Force

Mass Transfer Technology- Thin Film Transfer Technology: VueReal

Solid Printing

Mass Transfer Technology- Thin Film Transfer Technology: Rohinni

Alignment Pin

Mass Transfer Technology- Thin Film Transfer Technology- Fluidic Assembly Technology

Mass Transfer Technology- Thin Film Transfer Technology: eLux

Fluidic Assembly

Mass Transfer Technology- Thin Film Transfer Technology: PlayNitride

Fluidic Transfer

Mass Transfer Technology- Thin Film Transfer Technology- Laser Transfer

Mass Transfer Technology- Thin Film Transfer Technology- Laser Transfer Classification

Mass Transfer Technology- Thin Film Transfer Technology: Sony

Laser Transfer

Mass Transfer Technology- Thin Film Transfer Technology: QMAT

BAR(Beam-Addressed Release) Mass Transfer

Mass Transfer Technology- Thin Film Transfer Technology: Uniqarta

Multi-Beam Transfer

Mass Transfer Technology- Thin Film Transfer Technology: OPTOVATE

Laser Lift-off (ρ-LLO) Technology

Mass Transfer Technology- Thin Film Transfer Technology- Roll to Roll Transfer

Mass Transfer Technology- Thin Film Transfer Technology: KIMM

Roll to Roll Transfer

Mass Transfer Technology- Seven Major Challenges of Micro LED Mass Transfer Technology

Mass Transfer Technology- Transfer Yield Depends on the Control of Manufacturing Capability

Mass Transfer Technology- Applicability Analysis

Chapter 8 Testing Technology Bottleneck and Challenge Analysis

Micro LED Technology Bottleneck and Solution Overview- Testing Technology

Testing Technology- Testing Method

Testing Technology- Electrical Properties

Testing Technology- EL

Testing Technology- Light Properties

Testing Technology- PL

Testing Technology- Overview of Mass Testing Technology

Mass Testing Method- PL Testing Technology

Mass Testing Method- Digital Camera Photoelectric Testing Technology

Mass Testing Method- Contact Photoelectric Testing Technology

Mass Testing Method- Contactless Photoelectric Testing Technology

Mass Testing Method- Contactless EL Testing Technology

Mass Testing Method- Ultraviolet Irradiation Photoelectric Testing Technology

Mass Testing Technology Difference Comparison

Chapter 9 Repairing Technology Bottleneck and Challenge Analysis

Micro LED Technology Bottleneck and Solution Overview- Repairing Technology

Micro LED Repairing Technology Solution

Repairing Technology Solution- Ultraviolet Irradiation Repairing Technology

Repairing Process of Micro LED Dead Pixel

Repairing Technology Solution- Ultraviolet Irradiation Repairing Technology

Dead Pixel Repairing Technology Analysis

Repairing Technology Solution- Ultraviolet Irradiation Repairing Technology

Transfer Head Pickup Process

Repairing Technology Solution- Laser Welding Repairing Technology

Repairing Technology Solution- Selective Pick Repairing Technology

Repairing Technology Solution- Selective Laser Repairing Technology

Repairing Technology Solution- Backup Circuit Design Solution

Micro LED Active Defect Detection Design

Chapter 10 Full Color Technical Bottleneck and Challenge Analysis

Full Color Technical Solution Types

Full Color Technical Solution - RGB Chip Colorization Technique

Full Color Technical Solution - RGB Chip Colorization Techniqueisgychnologygyi

Full Color Technical Solution - Color Conversion Technology

Full Color Technical Solution - Qunatum Dot Color Conversion Technology and Application

Full Color Technical Solution - Quantum Well (QW) Color Conversion Technology

Full Color Technical Solution - Overview

Full Color Technical Solution - Applicability Analysis

Chapter 11 Bonding Technical Bottleneck and Challenge Analysis

Bonding Technology - Technical Classification

Bonding Technology - SMT Solution

Bonding Technology - Eutectic Wave Soldering Assembly Technical Solution

Bonding Technology - Anisotropic Conductive Adhesive (ACF) Solution

Bonding Technology - Anisotropic Solder Paste (SAP) Solution

Bonding Technology - Wafer Bonding Technical Solution

Bonding Technology - Wafer Bonding Difficulty Analysis

Bonding Technology - Micro TUBE Solution

Bonding Technology - Technical Difficulty Analysis

Bonding Technology - Feasibility Analysis

Chapter 12 Analysis of driving scheme bottlenecks and challenges

Driving Technology- driving scheme types

Driving Technology- the importance of driver IC

Driving Technology- Relationship Between V-I Characteristics and Luminance of LED

Driving Technology- Types of Switch Mode Driver

Driving Technology- Relationship between PWM and Duty Cycle

Driving Technology- Comparison between Active and Passive Matrix Driving

Driving Technology- Display Driving Scheme- Scanning Behavior and Refresh Rate

Driving Technology- Display Driving Scheme- Fine-pitch Display Analysis

Driving Technology- Thin Film Transistor- Driving Matrix of LCD displays

Driving Technology- Thin Film Transistor- Active Matrix (AM) V.S. Passive Matrix (PM)

Driving Technology- Thin Film Transistor- Analysis of Quality-affecting Factors

Driving Technology- OLED Driving Scheme- Photoelectric Properties of OLED

Driving Technology- OLED Driving Scheme- PMOLED

Driving Technology- OLED Driving Scheme- AMOLED

Driving Technology- Micro LED Driving Scheme- PM Micro LED

Driving Technology- Micro LED Driving Scheme- AM Micro LED

OLED V.S. Micro LED: Power Module Comparison

Chapter 13 Analysis of Backplane Technology Bottlenecks and Challenges

Backplane Technology- Structure of Display Backplane

Backplane Technology- Types of Backplane Material

Backplane Technology- Integrated Backplane: Operating Principles of Glass Substrate and Pixel Switch Components

Backplane Technology- Integrated Backplane: Features of Glass Substrate and Pixel Switch Components

Backplane Technology- Integrated Backplane: Size Development of Glass Substrate

Backplane Technology- Integrated Backplane: Thermal Expansion Challenges of Glass Substrate

Backplane Technology- Integrated Backplane: Application of Glass Substrate with Switch Components

Backplane Technology- Integrated Backplane: Structure of Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Manufacturing Process of a-Si Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Manufacturing Process of IGZO Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Manufacturing Process of LTPS Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Resolution Comparison of Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Power Consumption Comparison of Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Leakage Comparison of Pixel Switch Components for Glass Substrate

Backplane Technology- Integrated Backplane: Features of Flexible Substrate and Pixel Switch Components

Backplane Technology- Integrated Backplane: Manufacturing Process of Flexible Substrate

Backplane Technology- Integrated Backplane: Features of Flexible Substrate Materials

Backplane Technology- Integrated Backplane: Structure of Silicon Substrate

Backplane Technology- Integrated Backplane: Manufacturing Process of Silicon Substrate

Backplane Technology- Integrated Backplane: Features of Silicon Substrate Materials

Backplane Technology- Non-integrated Backplane: Outward Structure of PCB

Backplane Technology- Non-integrated Backplane: Inward Structure of PCB

Backplane Technology- Non-integrated Backplane: Thermal Effect of PCB

Backplane Technology- Non-integrated Backplane: Comparison of PCB Substrates

Backplane Technology- Non-integrated Backplane: Challenges of Manufacturing PCB

Backplane Technology- Non-integrated Backplane: Size Limit of PCB

Comparison of Backplane Technologies

Backplane Technology- Applicability Analysis

Chapter 14 Analysis of Micro LED Supply Chain and Technology Developments by Company

Analysis of Major Micro LED Developers (in the Supply Chain)

Analysis of Product Strategies and Technology Developments by Region- Taiwan

Analysis of Product Strategies and Technology Developments by Region- China

Analysis of Product Strategies and Technology Developments by Region- Korea

Analysis of Product Strategies and Technology Developments by Region- Japan

Analysis of Product Strategies and Technology Developments by Region- EU & the US

CN

TW

EN

CN

TW

EN