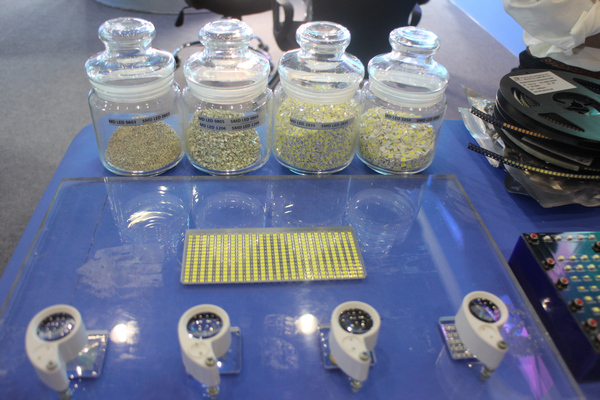

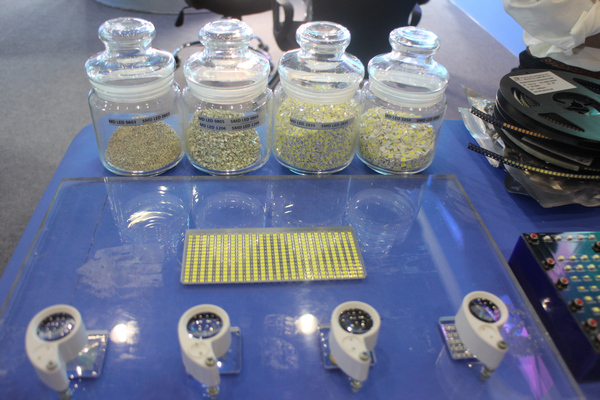

TP LED Lighting’s in-house 2835 LED package production capacity is sufficient enough to meet the production of at least 60,000 LED T8 tube lights, said the company’s Director Howard Huang during an interview with LEDinside at LED Expo Thailand 2015, which took place from May 21-24, 2015 at IMPACT Exhibition and Convention Center.

TP LED Lighting first spoke about plans of starting its own LED package production line in Samut Prakan Province, Thailand in November 2014. In its sixth year in the Thailand LED market, TP LED Lighting is one of the first companies to establish a factory in Thailand for in-house LED packaging.

Huang estimated the company’s in-house LED packaging capacity can meet the demands for 60,000 to 80,000 LED T8 tube lights per month, and about 144 LEDs are used in each tube.

This roughly is equivalent to an in-house LED packaging capacity ranging from 8.64 million to 11.52 million LEDs.

“Approximately 50% of the company’s LED package capacity are for our own products”, said Huang. At the moment, the company is mostly packaging 2835 LEDs.

|

|

TP Halo LED packages from left to right 0603, 0805,1206, 2835 and 5050 displayed at Ecolight Tech Asia 2014 were not displayed at LED Expo Thailand 2015. (LEDinside) |

In an earlier interview in November last year, Huang had stated the company might supply some of the LED packages to local Thai LED manufacturers, but in this recent interview he declined to comment whether the remaining 50% LED packages were supplied to local Thai LED manufacturers.

“We decided to set up our own in-house LED packaging capacity because it provides better flexibility and faster response time in meeting some client’s special customized demands,” said Huang. “Otherwise, we would have to wait for a very long time for the LED package imports.”

|

|

TP LED Lighting displayed some of its LED high bay lights for industrial lighting projects. The company is gradually shifting its focus from construction projects to selling its products through convenient and hardware stores. (LEDinside) |

Previously, the company business strategy had mostly been focused on construction projects, and government streetlight projects, but market conditions have forced the company to adjust.

“Before construction and government projects were very profitable, but the profits aren’t as good now, so we have to diversify our business strategy,” said Huang.

Delays in the government public tender market caused by reevaluations of streetlight projects under the new Royal Thai Army government, and slow payments were some of the reasons Huang cited for the transiting strategy.

The company is now investing more into developing its distribution channels in convenient and hardware stores, he added.

(Author: Judy Lin, Chief Editor, LEDinside)

CN

TW

EN

CN

TW

EN