LED technology has made great leaps in 2013. As LED prices continue to fall, large LED manufacturers are focusing on packaging process and material to develop low cost technologies. “Package free technology” has no doubt become the most important technological breakthrough this year that has surprised the industry. Unistars has been using advanced wafer package technology, Chip Scale Package (CSP). The company has released its new CSP series product Mercury 1515 series, and is the first Taiwanese LED packager to mass produce CSP products.

|

|

Wayne Chyan, General Manager of C&C Office at Unistars. (LEDinside/ Unistars) |

“Package free technology” has become the most popular LED technology in 2013, with many large international brands announcing their new package free technologies. For instance, Philips Lumileds launched its Luxeon Flip Chip, Luxeon Q, while Cree is highlighting its XQ-E products. Unistar, though, has announced mass production of package free Mercury 1515 that is currently the smallest product with highest Cost/Performance (C/P). The product can meet client’s design application demands.

Unistars release of the world’s smallest 1515 CSP LED receives overwhelming support from clients

Unistar’s Mercury 1515 series uses most advanced CSP technology. The product is based on flip chip and omits wire bonding process to greatly increase the production and package yield. At the same time, it also uses metal bonding to raise the chip’s heat dissipation method. It also uses a unique patented copper substrate heat dissipation module, which has an ultra high heat transfer coefficient of approximately 400W/ mk packaged with flip chip’s metal eutectic bonding, the company has become a leader in the industry for low thermal resistance for ~4℃/W light source. This has effectively increased LED component’s heat dissipation efficiency, which greatly reduces LED’s internal heat accumulation and greatly extends the LED’s lifespan.

Mercury 1515’s can support direct current drive as high as 1.2A within an area of 1.5 mmX 1.5mm with brightness exceeding 260 lm. The product’s lumens per area have reached 13,000 lm/cm2, a much higher C/P than average LEDs. Aside from CSP series products excellent heat dissipation and efficiency, Mercury 1515 is much smaller compared to previous LED package components. The product has received market attention with its advantages of a five-sided emitter, beam angle of 150 degrees, and upgraded appearance.

CSP has become a product that has attracted attention from the LED industry in 2013. Those in the industry have paid close attention to the product’s mass production date, with Unistars first announcing mass production of CSP products for LED package manufacturers. Mercury 1515 capability of providing over 260 lm in such a limited area has given clients more design flexibility, and is price competitive, said Wayne Chyan, General Manager, C&C Office, Unistars. Clients have responded very warmly to the product, and Mercury 1515 is definitely a star product, Chyan added.

Mercury 1515 offers clients three important values

In response to the hot CSP trend in 2013, Chyan believes CSP will become the future trend for packaging. Unistars is using CSP technology as its basis in mass producing Mercury 1515, and also expanding production capacity to meet client demands. At the same time, the company has emphasized the product’s absolute price competitive advantages. In addition, Mercury 1515 has given clients larger design flexibility. Unistars Mercury 1515 application range is much larger and has more variability, and can also offer clients customized services.

“Unistars aim to provide clients a platform with excellent product quality,” said Chyan. The company’s LED R&D process is to meet client needs in different application markets.

|

|

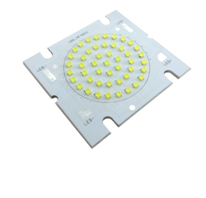

Unistars staggared array COB products. (LEDinside/ Unistars) |

Unistars promoted COB light source module improves COB product flaws

The company has also used Mercury 1515 products in its COB light module design, and launched COB light module products. Phosphor powder and other material costs used in COB packaging process remain relatively high, noted Chyan. If a single chip is damaged, the whole COB is unusable. In addition, conventional COB light sources tend to use small chips, which tend to have poor antistatic capacity which leads to future luminaire reliability problems. Unistars COB product not only solves the above mentioned issues, it also offers better lumens efficiency and light shape. Therefore, clients tend to directly replace their original COB products with Mercury 1515, which does not require additional replacement costs, and can meet client’s customized demands in a very short period of time.

COB products based on Mercury 1515 tend to have the most advantages in dual color temperatures or RGBA products. In dual color temperature COB products, the chip greatly reduces production yield issues. In terms of application, conventional dual color COB’s ring package method may also lead to image uniformity issues during client applications. Unistar’s COB LEDs uses staggered array design to achieve dual color temperatures, and successfully provide a uniform light source. At the same time it offers various color choices including red, green, blue, and amber. The 1515 LED is a single light source that satisfies client’s demands for different color temperature lights under different lighting scenarios. In addition, Mercury’s extremely small size can provide clients more flexibility and options in candle lamps, G9, incandescent lamps or 3D luminaires.

|

|

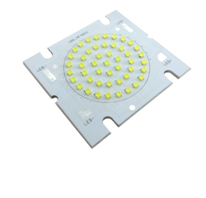

Two of Unistars COB products. (LEDinside/ Unistars) |

Unistars continual pursuit for excellence and release of even smaller sized CSP products

Accompanying increasing number of Mercury 1515 product series clients, Unistars expects to expand production capacity in 1Q14. Aside from expanding production capacity, Unistars currently is cooperating with large LED die manufacturers to achieve its aim of making 70 percent smaller next generation CSP LED sem¬¬iconductors. Once again the company is challenging the industry’s smallest sized LED, and providing clients LED products with higher C/P ratio.