Introduction

The emerging “Quantified Self” trend involves people monitoring, managing and tracking their health and wellbeing through digitalized biomedical information. Equipped with optical sensors, wearable devices such as smart watches and smartbands help consumers collect and measure different biological indicators and stats about themselves. Unlike the fiercely contested white LED market, the newly developing wearable device market is an untapped blue ocean market that presents incredible opportunities for the LED industry.

In an exclusive interview with LEDinside, Dr. Jörg Heerlein, Head of Product Marketing, Infrared Components, Industry and Distribution Division, Osram Opto Semiconductors (Osram Opto) touched upon the leading LED sensor manufacturer’s future developments, as well as its insights and outlook for the wearable application market.

|

|

The "Quantified Self" movement -- in short, self-knowledge through self-tracking with technology -- is growing. Millions of people are using fitness trackers, and the numbers are increasing. With the aid of optical sensors, trendy armbands and smartwatches can measure pulse rate and oxygen saturation in the blood. (All photos courtesy of Osram) |

How do LED based optical sensors in wearable devices measure biometric values?

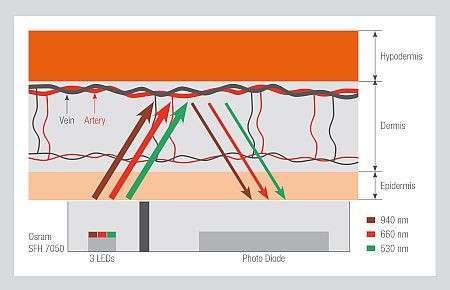

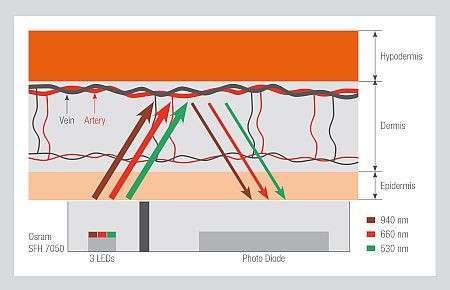

So how do LED sensors measure a person’s pulse rate and oxygen saturation in the blood? The principle measurement method has been photoplethysmography (PPG), which in theory is a measurement that absorbs reflected light from LEDs, explained Heerlein. The LEDs emit different wavelength of light that penetrates a person’s skin or other body tissues before being reflected back, which is then picked up by the sensor’s detectors. Data collected from the reflected light provides biometric readings that is used to determine a person’s physiological condition or wellbeing.

When PPG is used to determine pulse rate, it makes use of the fact that the red blood cells’ hemoglobin absorbs light. Moreover, the volume of blood in blood vessels changes as the heart cyclically expands and contracts as it pumps blood. Thus, sensors are able to establish a pulse rate by getting a reading from the reflected light. However, different locations on the body requires LED light of different wavelengths in order to get the best results. Green light of 530nm, for instance, are suitable for sensors worn on the wrists, and sensors for fingers generally carry red and IR light of 660nm and 940nm.

|

The principle of reflective optical pulse measurements. Light emitted by the sensor penetrates the skin and tissue and is absorbed or reflected back to the detector. (Photo Courtesy of Osram)

|

The same principle applies to measuring oxygen saturation of blood, with the red and IR light again being the standard wavelengths used by the optical sensors. The traditional method for monitoring changes in the blood vessels’ oxygen level requires blood samples to taken. LED optical sensors, by contrast, offers a non-invasive and therefore much more convenient detection method.

Future LED-based sensors new features on wearable devices

Heerlein especially emphasized Osram Opto’s most significant advantage: the ability to design and supply small integrated LED components that fits into wearable devices dimensions. The traditional design separates LED light, detector and other components, and this poses challenges when it comes to small sized wearable applications. Osram Opto, however, successfully devised a compact solution starting with the SFH 7050. This sensor component has a detector for reading blood oxygen level as well as three LEDs – green (530nm), red (660nm) and infrared (940nm). The miniature packaging of SFH 7050 allows it to be fitted onto a smartphone or other handheld devices.

The more advanced SFH 7051 adopts the same design as predecessor SFH 7050, but has a more efficient green LED chip that is based on the latest UX3 chip technology. Its integrated component additionally features pulse rate detection. OSRAM Opto is looking at ways to incorporate UV LED into its line of integrated sensor components as well, so wearable device users will be able to check their exposure to UV rays when their outdoors.

|

|

Osram's SFH 7051 LEDs for wearable device applications. |

Challenges in designing LED optical sensors for wearable devices

Heerlein expressed much optimism regarding the prospects of LED optical sensors in bio-monitoring application during the interview, but he also stressed there are several major challenges facing developers right now. According to Heerlein, getting reliable data is the biggest development hurdle for bio-monitoring sensors, since this involve professionals from the medical sector. Other concerns include the accuracy of the reading software and hardware design

LED optical sensors hardware designs are not always the most critical issue in wearable device developments. The respective wearable device makers may ultimately have to choose between power consumption and reliable data reading. Also, devising a system in verifying the data gathered by the sensor requires long-term research and testing by developers.

Conclusion:

With a positive outlook for LED-based optical sensor market, OSRAM Opto has largely invested resources and personnel into R&D and testing of related products.Heerlein believes the wearable application market has room for growth and expects his company will achieve impressive results.

(Author: Roger Chu, Research Director, LEDinside/ Translator: Thomas Hsu, Editor, TrendForce/ Editor: Judy Lin, Chief Editor, LEDinside)