(Author:Roger Chu, Research Director, LEDinsidehttp:// Translator: Judy Lin, Chief Editor, LEDinside)

In November 2015, Osram Opto Semiconductors (Osram Opto) announced general lighting will be an integral part of its long term strategic development plan, and that it would be investing EUR 1 billion (US$1.14 billion) in Malaysia to construct a 6-inch LED production site. The news surprised the entire LED industry. Recently, Osram Opto hosted a series of innovative SSL technology forums to unveil its new product line across Asia.

Osram’s innovative SSL technology forum in Shanghai, China.

|

|

Michael Schmitt, Regional Market Director, Asia-Pacific, Osram Opto Semiconductors delivering a talk at a forum in Shanghai recently. (All photos courtesy of LEDinside) |

|

|

Left to right: Michael Schmitt, Regional Market Director, Asia-Pacific, Osram Opto Semiconductors and Professor Taiming Zhou of Fudan University. |

Osram Opto’s new LED product line targets lighting market

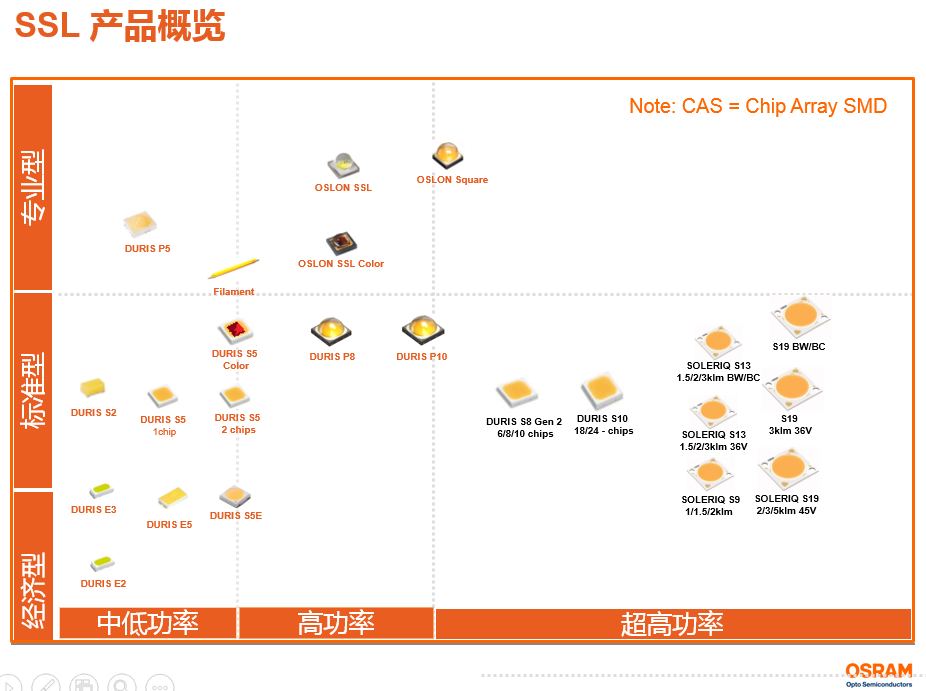

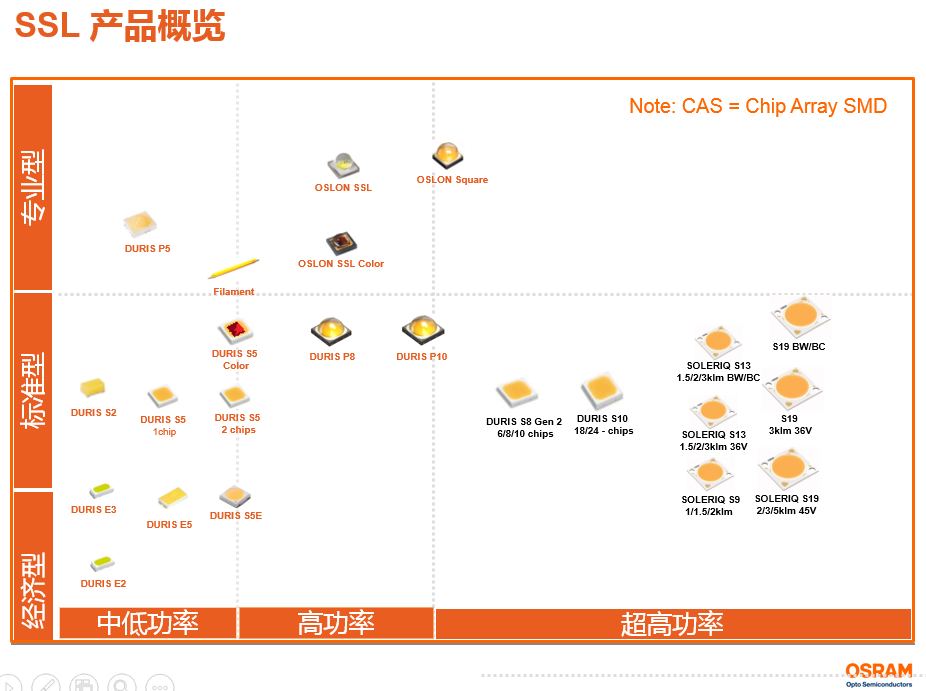

At the forum Osram showcased its comprehensive LED product portfolio that is targeting specific luminaire applications. The German company has been developing more than 100 LED components over the year to meet market trends, and differentiate its LED lighting products to meet various lighting application market demand, its product portfolio encompasses low to mid power LEDs with high C/P ratio, high power LEDs, new Chip Array SMD (CAS) and COB LEDs for high end commercial lighting applications, said Michael Schmitt, Market Director, Business Segment SSL, Osram Opto during an exclusive interview with LEDinside. To disentangle from the vicious price war cycle, Osram Opto is utilizing its key LED technology advantages, in LED chips, LED package, phosphor materials to make a perfect LED light source.

|

|

OSRAM Opto Product portfolio. |

|

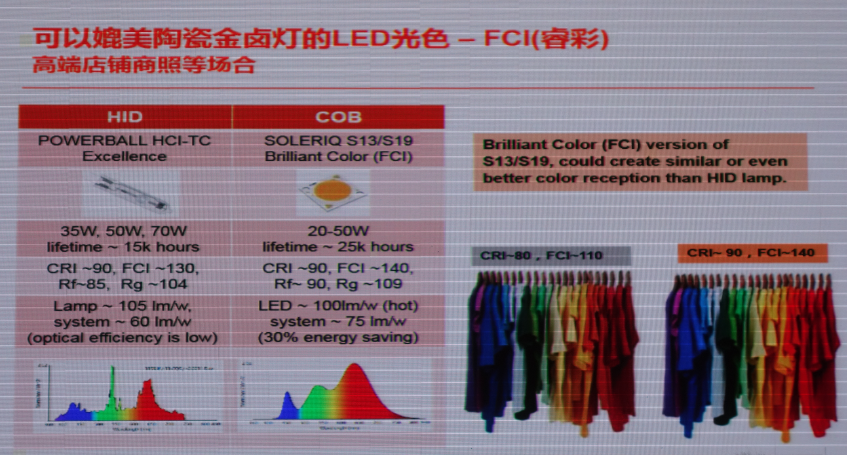

Osram’s innovative phosphor conversion technology in LED lights delivers better color reception performance than ceramic metal halide

Many of Osram’s clients are demanding for better lighting quality, especially in high-end commercial lighting applications. Hence, Osram Opto has incorporated Brilliant Color in Osram Opto’s Soleriq S13/S19 COB LED products, which gives LED light sources better color reception performance than ceramic metal halogens. The technology combined with innovative phosphor conversion technology can strengthen color gamut performance, and Feeling of Contrast Index (FCI) in its color performance index.

Osram’s 10° binning technology attracts attention at Light + Building 2016

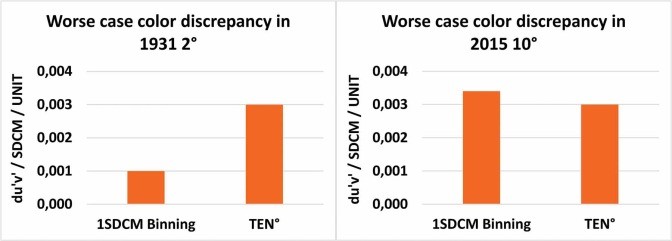

Color consistency among different LED luminaires is vital in commercial lighting applications, especially in high-end commercial lighting, museums and other lighting applications with high color uniformity demands. Even if LED manufacturers are able to manufacture LED luminaires with a color performance within 3-step MacAdam ellipse, there can still be color differences. Hence, many LED manufacturers are aiming to make LED light sources that deliver color performance within 2-step MacAdam ellipse and there are even those targeting performances of 1-step and below. By using higher Standard Deviation Color Matching (SDCM) standard, more stringent bin classification can be established to make higher quality light source. However, this also significantly raises costs, but does this really solve the issue?

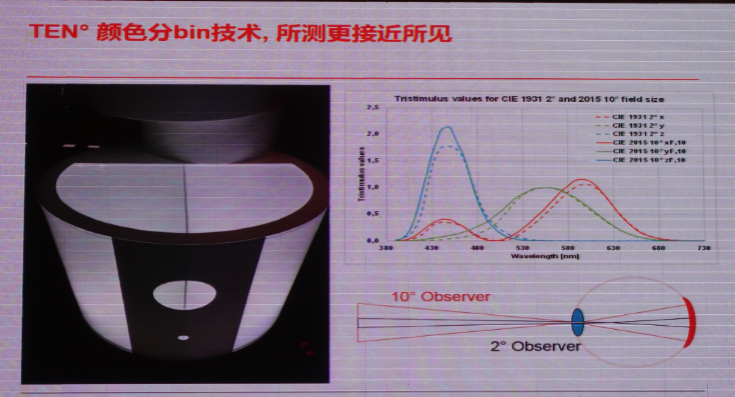

In response, Osram Opto proposed the 10° Binning concept. After releasing the technology at Light+ Building 2016, it was well received by LED lighting clients. Schmitt explains the concept behind 10° binning.

What is 10° binning?

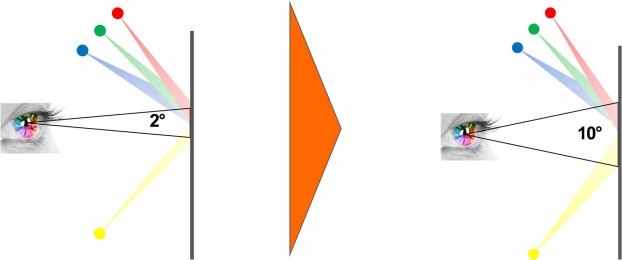

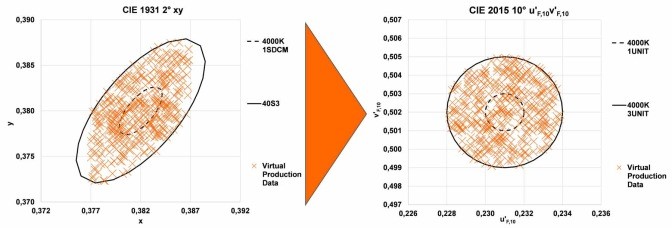

The majority of manufacturers in the LED industry are still using the conventional CIE 1931 2° xy color diagram for white LED binning, but differences in the blue chip wavelength or the converter composition can result in spectral differences and cause differences in visual color perception among light sources with the same color coordinates. To solve this issue, Osram incorporated CIE 170—2: 2015 technical report in LED binning.

In CIE 1931 the Tristimulus curves were determined by a 2-degree observer, whereas in CIE 170—2: 2015 they were determined by a 10-degree observer, which is changing the curves slightly. Since most of the SSL applications provide a field of view of 10° or more an assessment of the white appearance based on 2° will always be less representative than a comparison based on 10°.

Another change Osram did was shifting from the MacAdam ellipses xy scale to a u’v’ scale, which transforms the ellipse into a circle to create a more unified color space.

This technology is especially suited for lighting products that use a single light source, for example COB LEDs applied in spotlights, track lights and other products. Responding to industry concerns that 10° binning products will raise manufacturing costs, Schmitt noted the technology is only making the binning method smarter without making the specification necessarily even tighter. Osram will still bin its CoB in the standard 1931 2° color diagram. This ensures compatibility to existing standards and binnings. But additionally the new 2015 10° u’v’ TEN° binning will ensure the great color consistency in a smart and intelligent way